DISCRIPTIONS

Highly Environment-resistant Coordinate Measuring Machine, Allowing On-site Inspection outside the Measuring Room

• Has achieved an accuracy guaranteed temperature range of 10 to 40ºC thanks to the combination of technologies such as a symmetric structure, uniform material and temperature compensation.

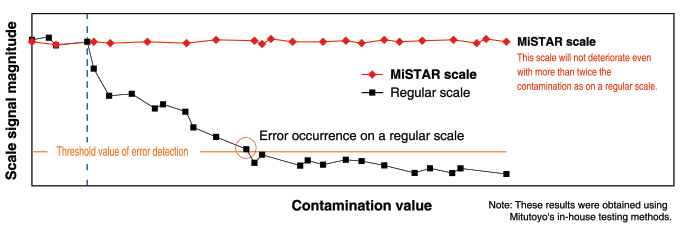

• Has achieved a contamination resistance more than 2 times better than Mitutoyo’s conventional machine by adopting a newly developed absolute scale* that is highly resistant to the challenging production-line environment.

*:A scale that provides an absolute value for each measurement point. This eliminates the need for an initialization operation.

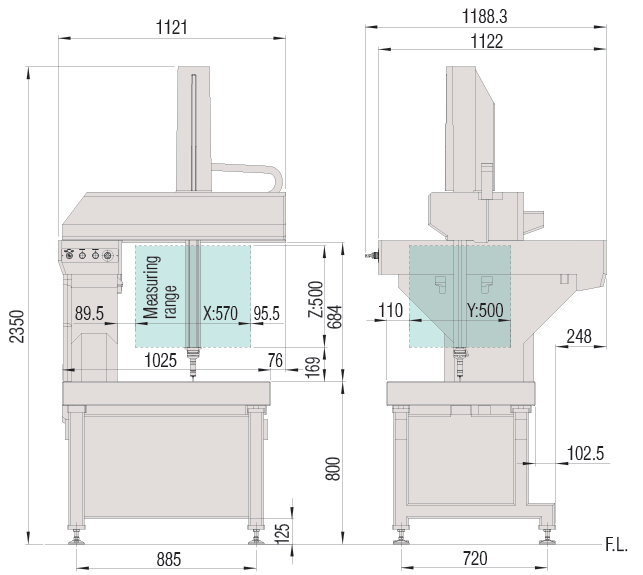

• Adopts the horizontal-arm structure and installs the CMM controller and PC under the measuring table to save installation space. This has reduced the footprint to about 70% compared with that of the conventional moving bridge model.

User-friendly Design Reduces Operator’s Workload

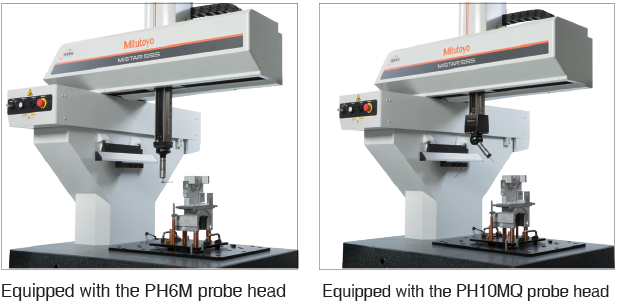

• The adoption of the horizontal-arm structure provides a three-sided open architecture, significantly easing the task of moving workpieces on and off the measuring table.

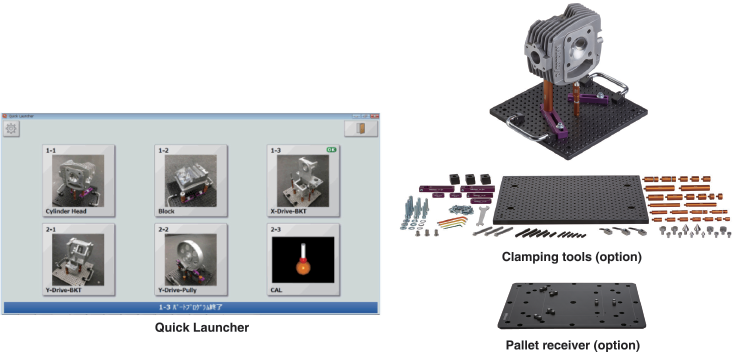

• Equipped as standard with Quick Launcher that enables simple and intuitive operation.

• The use of clamping tools and pallet receiver enables quick measurement of similar workpieces.

Note: Clamping tools and the pallet receiver are optional accessories.

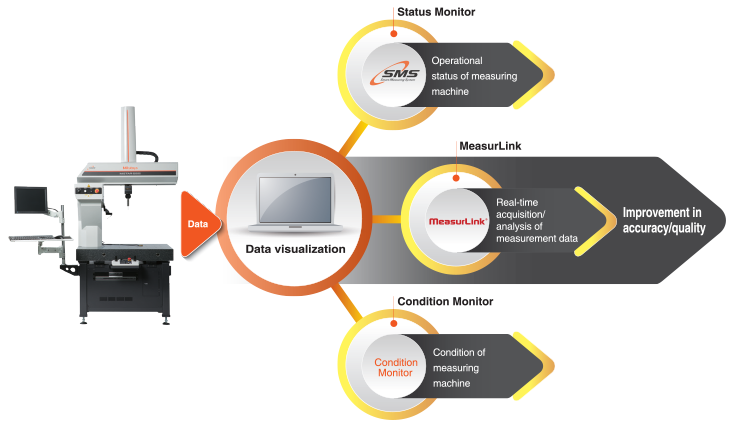

New Functionality has the “Smart Factory” in View

• From status control to preventive maintenance. Smart Factory starts with “visualization”.

• MiSTAR 555 is compatible with the following three applications that consolidate information management of the manufacturing process through a network.

Status Monitor : Allows remote monitoring of the operational status of measuring instruments.

Condition Monitor*1 : Allows remote monitoring of the current condition of measuring instruments.

MeasurLink*1 : Reduces the production of defective parts through “Visualizing Quality”.

SMS (Smart Measuring System)

This system allows on-line monitoring of the operational status of a measuring machine and visualization of measurement data produced during the manufacturing process to enable product quality improvement.