UBurr deburring tools provide you with an innovating way to remove your burrs.

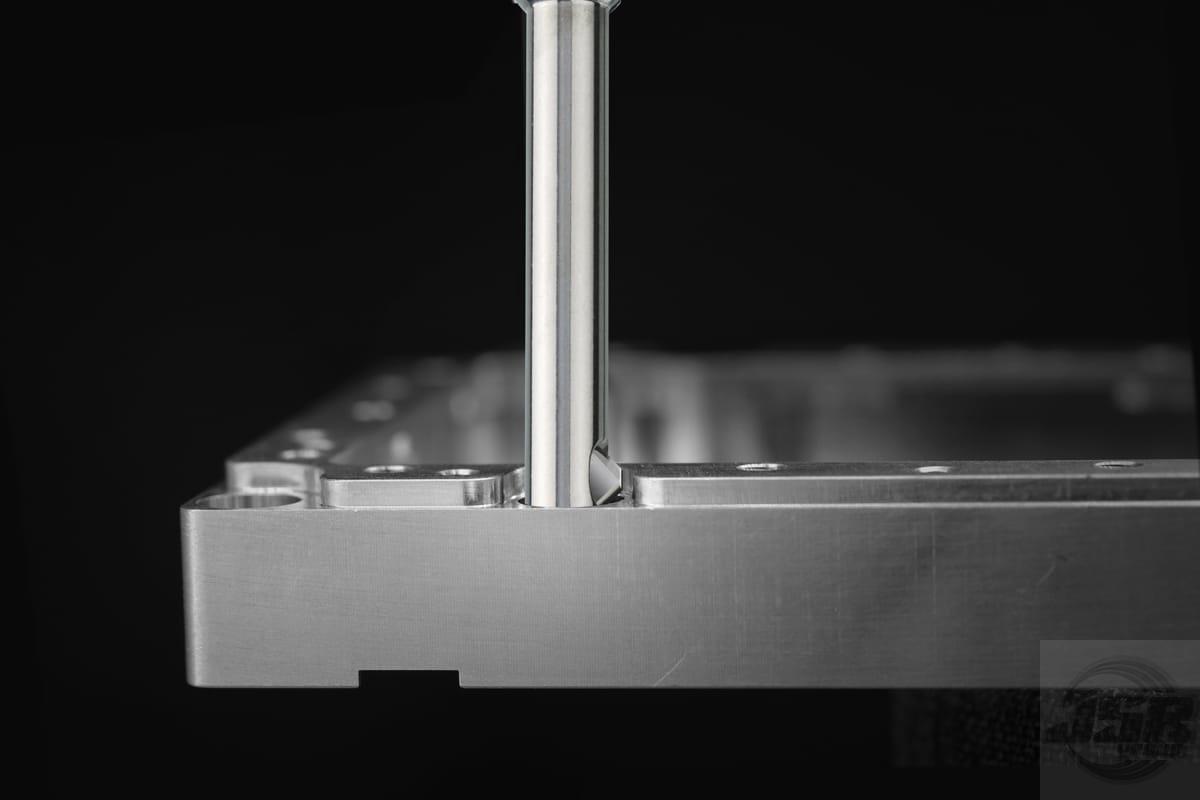

UBurr deburring tools providing a quick, effective, reliable and consistent deburring way of front and back side bore edges of a drilled hole in one single pass.

UBurr deburring tools radially removes the burrs off the bore edges, without requiring the workpiece to be turned or the spindle to be stopped.

This solution is faster, easier, and more economical for your hole deburring problems for small production and mass production as well.

UBurr deburring tool is a great choice for batch runs or in a production environment when a reliable and stable performance is required.

A simple and efficient mechanism for inserting and removing the blade.

The tool blade designed to easily deburr unwanted material from the front and back side of the holes in seconds.

The unique geometry prevents the blade from damaging the surface inside the hole.

The UBurr standard tool series range from Ø3 mm up to Ø25 mm.

Custom made tools can be made for your specific applications.

UBURR: THE TOOL PATH

ONE PASS SOLUTION TO HOLE-DEBURRING

♦1

The UBURR tools remove the burr from the front hole surface by a unique flexible blade.

♦2

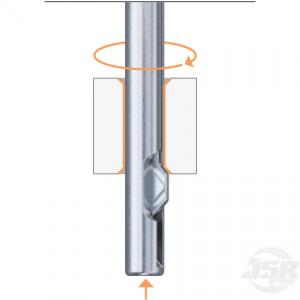

The UBURR blade enters into the tool pocket automatically as the pressure is increasing on the blade.

The unique geometry prevents the blade to damage the surface inside the hole.

♦3

The UBURR tools remove the burr from the back hole surface with the same spindle direction by going up.

BLADE INSERTION

1 Insert the blade into the holder slot until the blade stops at the holder pin.

2 Push the blade into the tool pocket.

3 Lock the screw clockwise.

BLADE REMOVAL

1 Remove the blade: Unlock the screw with Allen Key counterclockwise turn of the locking screw.

2 Push the blade by hexagon key through the technical hole.

3 Pull up the blade from the holder.