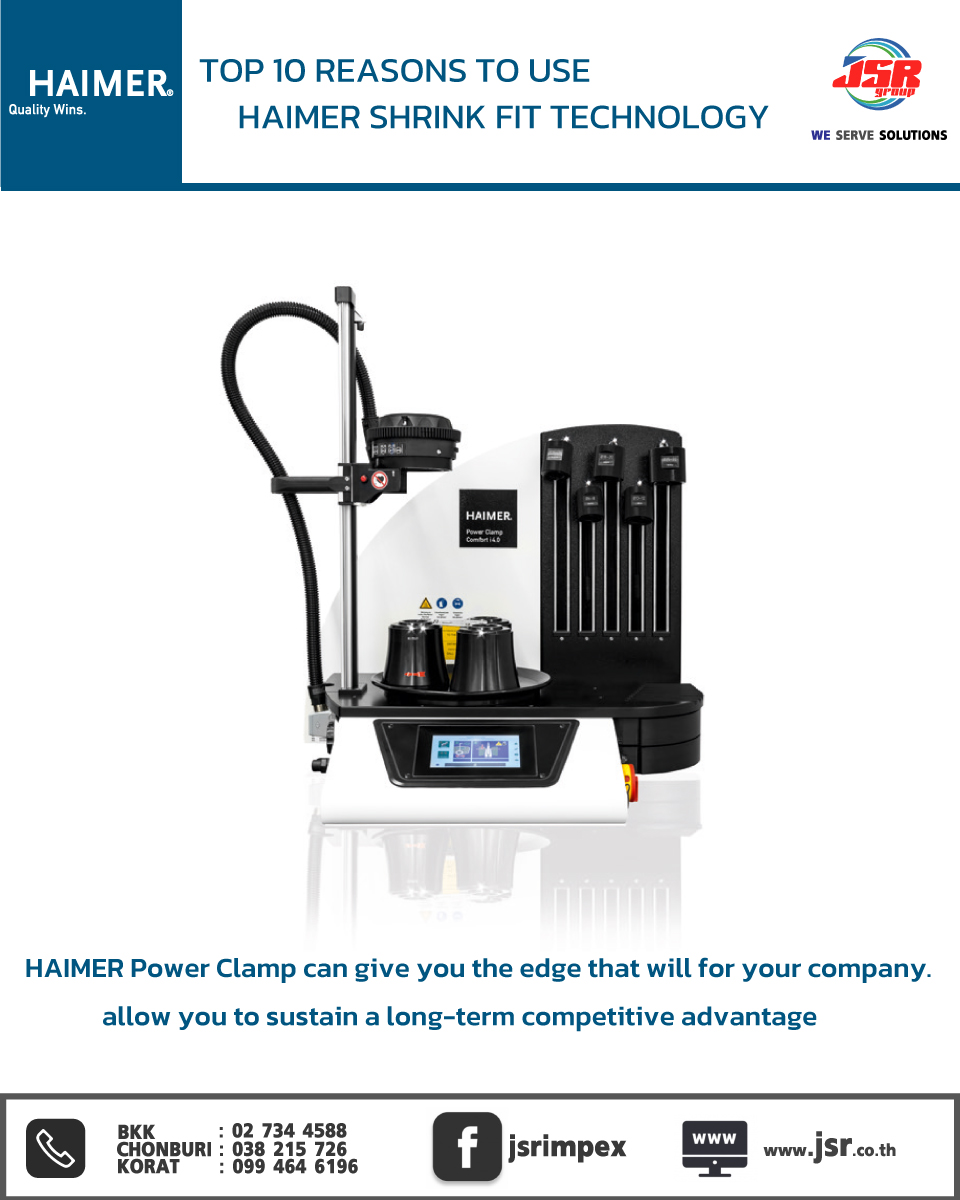

HAIMER Power Clamp can give you the edge that will

allow you to sustain a long-term competitive advantage

for your company.

1. Unsurpassed machining accuracy

We guarantee < 3µm run-out at 3xD. This degree of accuracy is

consistently repeatable for any number of operators from shift to shift.

2. Slim profiles

HAIMER Shrink Fit tool holders have very slim profiles. They can also be

modified to a straight-walled design if needed in order to prevent tool

holder collision with the workpiece.

3. Gripping torque

Our shrink fit chucks grip the cutting tool 360° around the shank on

multiple planes, delivering very high gripping torque that prevents chatter during roughing or finishing operations.

4. Consistency of setup

A unique benefit of HAIMER shrink fit is that it eliminates any variation between tool changes. Removing these

variables means regardless of the operator and their experience level, you will get repeatable

uniformity in tooling setup and equally consistent results.

5. Extended reach options

Shrink fit extensions provide many options. For example, when machining deep cavities, you can place shrink fit

extensions into standard shrink fit chucks, getting unsurpassed gage lengths with minimal run-out.

6. Balance accuracy and repeatability

We hold our shrink fit holders to the highest balance accuracy standards (G2.5@ 25,000 RPM). Since shrink fit

holders have no moving parts, it offers the best balance repeatability of any tool holding system on the market.

7. Reduction of tool changing time and less tool holder accessory inventory

Nothing beats the tool change time of our shrink fit chucks when combined with our Power Clamp shrink fit

machines. Tool changes can be done in less than 5 seconds.

8. Clean bores

Run-out accuracy is often compromised if contaminants are introduced to the bore of a tool holder during

machining. A shrink fit chuck is a sealed system by design. This minimizes the introduction of contaminants.

9. Coolant options

Our shrink fit chucks are available with a variety of coolant options, including our Cool Jet and Cool Flash

technology, which delivers coolant down to the cutting edge of the tool. This helps clean out chips and can aid in

providing better part finishes.

10. Availability

Bestseller machines are available and stocked locally. All other configurations and modifications are available per

order within just a couple of weeks.

📧 Email: marketing2@jsr.co.th

—————————————————————-

J.SRI RUNG RUENG IMPEX CO.,LTD. (กทม. ลาดกระบัง)

TEL : 02-327-0351-5, 02-734-4588

Line : jsri_nopporn

—————————————————————-

C.DUREON MACHINE AND TOOLS CO.,LTD. (ชลบุรี)

TEL : 038-743-414-21, 038-215-725-8, 061-401-2144-8

Line : cdc-jsrgroup

—————————————————————-

JSR GROUP (KORAT) CO.,LTD (โคราช)

Tel : 099-464-6196

Email : dulphinit@jsr.co.th

Line : jsrgroupkorat

—————————————————————-

#shrinkfit #powerclamp #haimer #jsrgroup