HAIMER Automation

Automation in the tool room – HAIMER is your system partner

The HAIMER Group has developed to a system partner for the entire tool management around the machine tool. As such, HAIMER is consistently driving the idea of automation and digitization. The latest highlight is the HAIMER Automation Cube, a robot cell that can be used to completely automate the tool presetting process.

>>> another product of haimer click here

-

2109A-70 | Dial Indicator SERIES 2 — Water-proof Type, 0.01 mm & 0.001 mm Graduation | MITUTOYO

Dial Indicator SERIES 2 — Standard Type, 0.001 mm & 0.005 mm Graduation | MITUTOYO

• Water-proof type dial indicators having a bezel with an outside diameter of 57 mm.

• O-rings and rubber bellows are used to prevent water and oil penetration.

• The bezel clamp can be attached to either the right or left side. These parts can be easily installed and removed without tools.

• The stem and spindle are made of high-strength quench-hardened stainless steel suitable for heavy-duty use.

• A carbide contact point is used.

• Application of an anti-reflective and hard surface coating improves scale visibility along with scratch and chemical resistance.หมวดหมู่: Okazaki ป้ายกำกับ: 2109A-70, Dial Indicator, Graduation, Mitutoyo, SERIES 2, Water-proof Type -

AL-SP 1.5P | Spiral Fluted Taps for Aluminum – ต๊าปร่องเลื้อยสำหรับอลูมิเนียม | YAMAWA

AL-SP 1.5P

SPIRAL FLUTED TAPS FOR ALUMINUM

ต๊าปร่องเลื้อยสำหรับอลูมิเนียม

Recommended Tapping Speeds depending on Materialsความเร็วรอบจะขึ้น อยู่กับวัสดุที่ใช้ในการต๊าป

■ In aluminum die casting and aluminum casting tapping, AL-SP solves such problems as chip jamming, chip clogging, and torn threads.

■ ใช้กับอลูมิเนียมหล่อ และ อลูมิเนียมฉีด, โดยลดปัญหาการเกิดเศษตัด, เศษหักเชื่อม** กรุณาระบุขนาดที่ต้องการในการขอราคาสินค้า**

หมวดหมู่: Cutting Tools เครื่องมือกัดแต่งโลหะ, for Aluminum, Spiral fluted taps for blind hole, Tap, YAMAWA ป้ายกำกับ: CUTTING TOOLS, SP, Spiral fluted taps, TAP, yamawa, ต๊าป, ต๊าปร่องเลื้อย -

AL+SP / AL-SP | Spiral Fluted Taps for Aluminum – ต๊าปร่องเลื้อยสำหรับอลูมิเนียม | YAMAWA

AL+SP / AL-SP

SPIRAL FLUTED TAPS FOR ALUMINUM

ต๊าปร่องเลื้อยสำหรับอลูมิเนียม

Recommended Tapping Speeds depending on Materialsความเร็วรอบจะขึ้น อยู่กับวัสดุที่ใช้ในการต๊าป

• AL + SP ensures the consistent tapping even in high speed cutting area, in forged workpieces of light alloys such as aluminum die casting and aluminum casting.

• Having optimum cutting edge design, AL + SP does not produce burrs in minor diameter which usually tend to come out during tapping light alloys, and results in cutting of stable and clean internal threads.• AL+SP สามารถใช้กับงานที่มีรอบความเร็วสูงได้ ใช้กับชิ้นงานที่เป็นโลหะเบา เช่น อลูมิเนียมหล่อฉีด และอลูมิเนียมหล่อ

• เนื่องจากการออกแบบคมตัดที่เหมาะสม AL+SP จะไม่ทำให้เกิดครีบ (bari) ในส่วนของ Minor diameter ที่มักจะเกิดครีบในโลหะเบา ทั้งยังให้ผลลัพธ์ในการต๊าปที่ดี และได้เกลียวที่สะอาดเรียบ** กรุณาระบุขนาดที่ต้องการในการขอราคาสินค้า**

หมวดหมู่: Cutting Tools เครื่องมือกัดแต่งโลหะ, for Aluminum, Spiral fluted taps for blind hole, Tap, YAMAWA ป้ายกำกับ: CUTTING TOOLS, SP, Spiral fluted taps, TAP, yamawa, ต๊าป, ต๊าปร่องเลื้อย -

ASPV mini | POLISH MILL V TYPE | MOLDINO

POLISH MILL V TYPE ASPV mini

Brand: MOLDINO

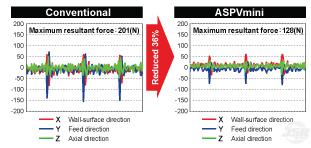

We’ve added high-precision finishing tools to our small-diameter multi-flute cutting tool series.

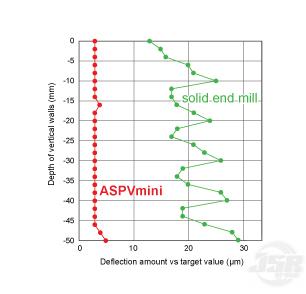

The free-cutting edge shape solves issues related to vertical wall cutting.ISUUE 01 : Inability to achieve desired dimensional accuracy with deflected walls.

Reworking consumes much time.Proposed solutions

● Insert shapes with enhanced free-cutting capabilities enable to precisely finish deep vertical walls with extended overhangs.

● ASPVmini decreases wall deflection, reducing the time spent on reworking, additional work and modification issues during the finishing process.Cutting condition

Work material : S50C (220HB)

Machine : Vertical type (BT40)

Point ! > Ground chipbreaker

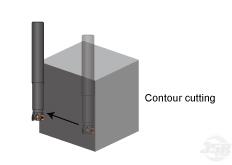

ISUUE 02 : Requires high verticality, even at deep points where the L/D※ is eight or greater.

※L/D:Ratio of tool diameter (D) and tool overhang (L)

Proposed solutions

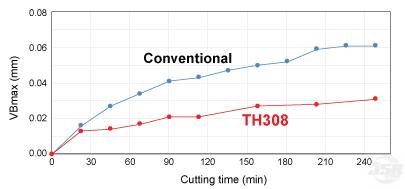

● Vertical cutting improves vertical wall accuracy, even when it’s difficult to cut the wall at constant depth due to extremely long overhangs.ISUUE 03 : The tool wears due to prolonged finishing, resulting in unstable surface grade or problems with dimensional accuracy.

Proposed solutions

The ASPVmini inserts use the new grade “TH308” which offers excellent abrasion resistance to maintain high surface grade and accuracy.

Machine:Vertical 3-axis M/C (HSK63)

Work material:Equivalent to SKD61 (45HRC)

Tool: Body ASPVM1012R-3-M6

Insert MPHT040205ZEL-0.5

Cutting speed:Vc = 250m/min

Feed rate: fz=0.1mm/t

Axial depth of cut (ap)=1.0mm

Radial depth of cut (ae)=0.1mm

Air-blow** หากต้องการใบเสนอราคา กรุณาระบุ เลข order no. ของขนาดที่ต้องการให้ชัดเจน **

หมวดหมู่: Cutting Tools เครื่องมือกัดแต่งโลหะ, INDEXABLE TOOL, MOLDINO, Square ป้ายกำกับ: ASPV mini, CUTTING TOOLS, INDEXABLE TOOL, Inserts, MOLDINO

-

ASRT TYPE | RADIUS MILL 3CORNER | MOLDINO

RADIUS MILL 3 CORNER ASRT TYPE MOLDINO

AJ Coating series

• Features of AJ Coating series

・Employs an AlTi layer with a new composition created by increasing the Al content of conventional layers.

・Excellent wear resistance, chipping resistance, and heat resistance!• New technology!!

・The new layer with high Al content employs a new composition and optimizes the crystal structure to improve wear resistance and chipping resistance!

・Employs a low-friction-effect coating with excellent welding resistance as the top-most surface layer. This reduces welding to the work and decreases cutting force!หมวดหมู่: Cutting Tools เครื่องมือกัดแต่งโลหะ, INDEXABLE TOOL, Moldino, Radius ป้ายกำกับ: ASRT, INDEXABLE TOOL, INSERT, MOLDINO, Radius mill -

AU+SP | PLUS SERIES SPIRAL FLUTED TAPS, Optimum Coating for the tapping – ต๊าปร่องเลื้อยตระกูลบวก, เคลือบผิว | YAMAWA

AU+SP

PLUS SERIES SPIRAL FLUTED TAPS, Optimum Coating for the tapping

ต๊าปร่องเลื้อยตระกูลบวก, เคลือบผิว

Recommended Tapping Speeds depending on Materialsความเร็วรอบจะขึ้น อยู่กับวัสดุที่ใช้ในการต๊าป

• AU+SP has a special thread portion design with thread crests ground off and a few full threads after chamfer left unchanged.

• Effects of AU+SP are as follows:

– Prevention of chipping trouble at full thread portion

– Reduction of tapping torque and tapping friction

– Good chip ejection• AU+SP มีเหลียวที่ถูกออกแบบมาพิเศษ โดยปรับปรุงที่ร่องคายเศษ และเพิ่มเกลียวเต็มให้ส่วนเกลียวหลังแชมเฟอร์

• ผลของ AU+SP มีดังต่อไปนี้

– ป้องกันการแตกหักของเกลียวเต็ม

– ลดแรงบิด และแรงเสียดทานในการต๊าป

– การคายเศษมีประสิทธิภาพ** กรุณาระบุขนาดที่ต้องการในการขอราคาสินค้า**

หมวดหมู่: Cutting Tools เครื่องมือกัดแต่งโลหะ, for Steel, Spiral fluted taps for blind hole, Tap, YAMAWA ป้ายกำกับ: CUTTING TOOLS, SP, Spiral fluted taps, TAP, yamawa, ต๊าป, ต๊าปร่องเลื้อย -

AUXSP | X SERIES SPIRAL FLUTED TAPS, COATED – ต๊าปร่องเลื้อยตระกูลเอ็กซ์, เคลือบผิว | YAMAWA

AUXSP

X SERIES SPIRAL FLUTED TAPS, Coated

ต๊าปร่องเลื้อยตระกูลเอ็กซ์, เคลือบผิว

Recommended Tapping Speeds depending on Materialsความเร็วรอบจะขึ้น อยู่กับวัสดุที่ใช้ในการต๊าป

Use with dedicated toolings is recommended.

เลือกใช้เครื่องมือให้ตรงกับข้อแนะนำ■ Applying the blanks of high toughness and high accuracy, AUXSP derives the maximum performance from high facility machining centers and high precision toolings. Special thread portion design with thread crests ground off and a few full threads left unchanged. Combination of this design and the special flute geometry maintains good chip ejection and reduces friction. The Spiral Fluted Tap is adopting the optimum coating for the tapping condition.

■ ในการใช้วัสดุทำต๊าบที่มีความแข็งแรง และเที่ยงตรงสูง ส่งผลให้ AUXSP เป็นต๊าปที่มีประสิทธิภาพสูง รวมกับการออกแบบร่องคายเศษ ส่วนของเกลียว และลักษณะของฟัน ต๊าปแบบพิเศษ ทำให้ได้การต๊าปที่มีประสิทธิภาพสูง สามารถขับเศษได้ดี และลดแรงเสียดทานในการต๊าป** กรุณาระบุขนาดที่ต้องการในการขอราคาสินค้า**

หมวดหมู่: Cutting Tools เครื่องมือกัดแต่งโลหะ, for Steel, Spiral fluted taps for blind hole, Tap, YAMAWA ป้ายกำกับ: CUTTING TOOLS, SP, Spiral fluted taps, TAP, yamawa, ต๊าป, ต๊าปร่องเลื้อย -

E-SP | SPIRAL FLUTED TAPS FOR SOFT STRUCTURAL STEELS – ต๊าปร่องเลื้อยสำหรับเหล็กนิ่ม | YAMAWA

E-SP

SPIRAL FLUTED TAPS FOR SOFT STRUCTURAL STEELS

ต๊าปร่องเลื้อยสำหรับเหล็กนิ่ม

Recommended Tapping Speeds depending on Materialsความเร็วรอบจะขึ้น อยู่กับวัสดุที่ใช้ในการต๊าป

■ Suitable particularly for soft steels such as SS41, S25C and the like

■ เหมาะสมกับเหล็กที่มีโครงสร้างนิ่ม เช่น SS41, S25C** กรุณาระบุขนาดที่ต้องการในการขอราคาสินค้า**

หมวดหมู่: Cutting Tools เครื่องมือกัดแต่งโลหะ, for Steel, Spiral fluted taps for blind hole, Tap, YAMAWA ป้ายกำกับ: CUTTING TOOLS, SP, Spiral fluted taps, TAP, yamawa, ต๊าป, ต๊าปร่องเลื้อย