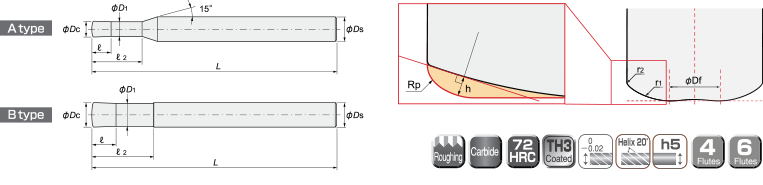

FEATURES

Features of EHHRE-TH3

- Approximate radius makes much thinner chip than real radius

- Vibration-free peripheral clearance geometry

- Newly developed coating “TH3” for hardened steel machining

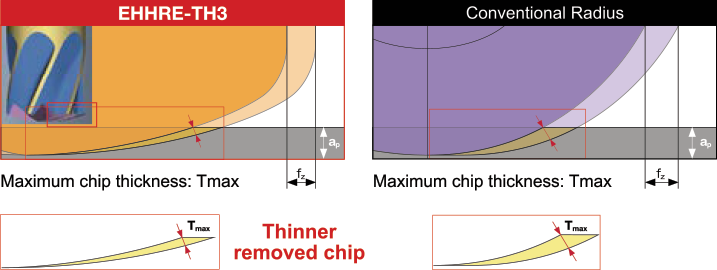

Feature 1 : New Cutting Edge Geometry – Approximate radius makes much thinner chip than real radius

Effect : Composite R geometry on bottom cutting edge could create thinner chips than conventional radius geometry (real R), and it enables to reduce cutting force.

Furthermore, by making the bottom edge a high helix shape, it improves the chip flow. And achieves excellent chip discharging performance.

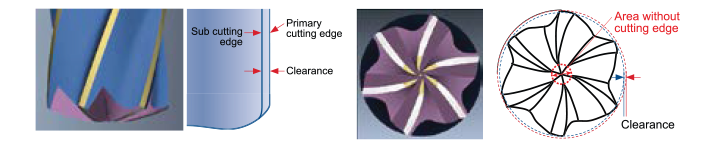

Feature 2 : Peripheral clearance geometry to reduce vibration

■ Vibration-free peripheral clearance geometry

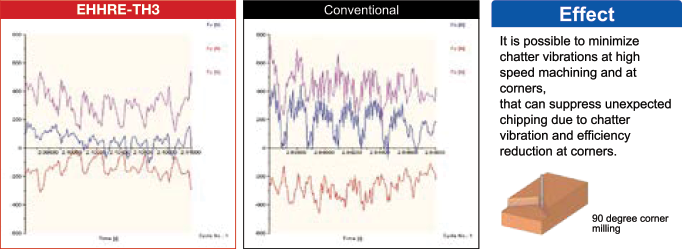

■ Effect to suppress vibration at corner milling

Work material:DACⒽ 49HRC Machine:Vertical MC (HSK-A63) Tool:EHHRE6100-TH3

Cutting conditions:n=6,000min-1(vc=188m/min) vf=1,800mm/min (fz=0.05mm/t)

Cutting amount :0.3mm, Dry with air blow

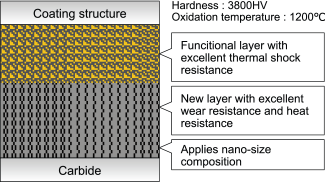

Feature 3 : Newly developed coating “TH3” for hardened steel machining

■ Features and performance

・High hardness coating with excellent wear resistance and heat resistance

・Has excellent thermal shock resistance enables to suppress sudden chipping

・Long tool life when cutting high-hardness materials (50HRC or higher) such as hardened steel

■ Target steel grade

・Hardened steel (especially 50HRC or higher), high-speed steel