- Sort by Default Order

- Display 12 Products per page

-

ASPV mini | POLISH MILL V TYPE | MOLDINO

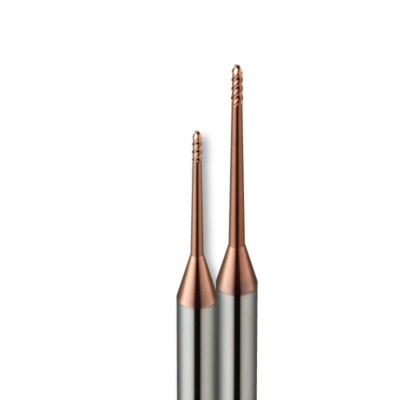

POLISH MILL V TYPE ASPV mini

Brand: MOLDINO

We’ve added high-precision finishing tools to our small-diameter multi-flute cutting tool series.

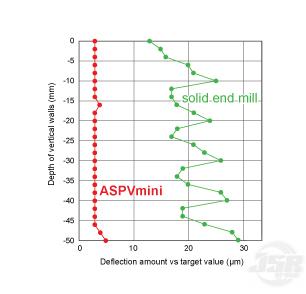

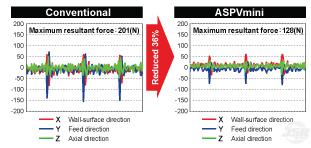

The free-cutting edge shape solves issues related to vertical wall cutting.ISUUE 01 : Inability to achieve desired dimensional accuracy with deflected walls.

Reworking consumes much time.Proposed solutions

● Insert shapes with enhanced free-cutting capabilities enable to precisely finish deep vertical walls with extended overhangs.

● ASPVmini decreases wall deflection, reducing the time spent on reworking, additional work and modification issues during the finishing process.Cutting condition

Work material : S50C (220HB)

Machine : Vertical type (BT40)

Point ! > Ground chipbreaker

ISUUE 02 : Requires high verticality, even at deep points where the L/D※ is eight or greater.

※L/D:Ratio of tool diameter (D) and tool overhang (L)

Proposed solutions

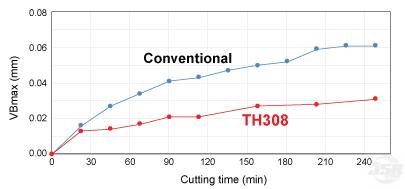

● Vertical cutting improves vertical wall accuracy, even when it’s difficult to cut the wall at constant depth due to extremely long overhangs.ISUUE 03 : The tool wears due to prolonged finishing, resulting in unstable surface grade or problems with dimensional accuracy.

Proposed solutions

The ASPVmini inserts use the new grade “TH308” which offers excellent abrasion resistance to maintain high surface grade and accuracy.

Machine:Vertical 3-axis M/C (HSK63)

Work material:Equivalent to SKD61 (45HRC)

Tool: Body ASPVM1012R-3-M6

Insert MPHT040205ZEL-0.5

Cutting speed:Vc = 250m/min

Feed rate: fz=0.1mm/t

Axial depth of cut (ap)=1.0mm

Radial depth of cut (ae)=0.1mm

Air-blow** หากต้องการใบเสนอราคา กรุณาระบุ เลข order no. ของขนาดที่ต้องการให้ชัดเจน **

-

ASRT TYPE | RADIUS MILL 3CORNER | MOLDINO

RADIUS MILL 3 CORNER ASRT TYPE MOLDINO

AJ Coating series

• Features of AJ Coating series

・Employs an AlTi layer with a new composition created by increasing the Al content of conventional layers.

・Excellent wear resistance, chipping resistance, and heat resistance!• New technology!!

・The new layer with high Al content employs a new composition and optimizes the crystal structure to improve wear resistance and chipping resistance!

・Employs a low-friction-effect coating with excellent welding resistance as the top-most surface layer. This reduces welding to the work and decreases cutting force! -

TD4N type | RADIUS MILL | MOLDINO

Radius Mill TD4N type

Lineup expanded with insert for high-hardness materials

Technology

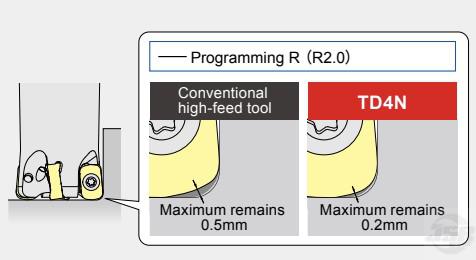

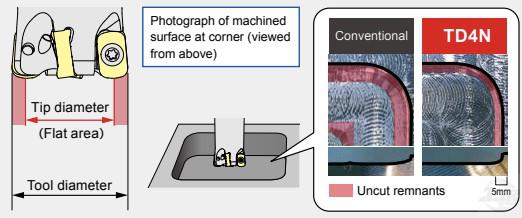

Features 1 Reduces uncut remnants on work pieces

The cutting edge shape was reviewed for TD4N so that uncut remnants are reduced.

This enables the load on the next process to be reduced by up to 40%compared to

conventional products.● Since it is difficult to create tool shape definitions in CAM for the complicated cutting edge shapes of high-feed tools, in many cases the tools are used with the definition for a simple R radius tool. The differences between this definition and the actual tool shape result in uncut remnants that cannot be checked on CAM and become more work for the next process.

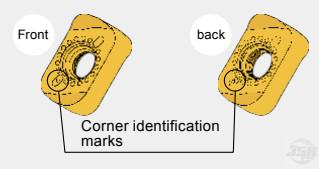

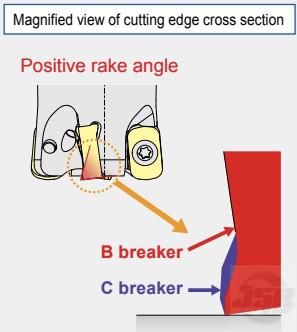

Features 2 Economical 4-corner inserts with chip breakers for various applications

●By making it possible to use both the front and back sides of inserts, 4 corners can be used. The inserts are provided with a large rake angle which exhibits an excellent cutting force reduction effect even when compared to general positive-shape inserts.

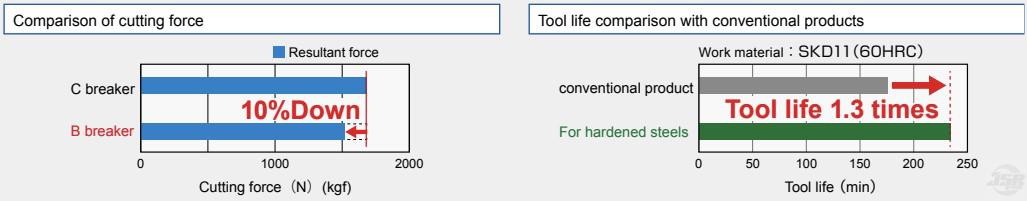

⦿Features of insert breaker

C breaker

Corresponds to our general high-feed-type inserts (EDNW, EPNW,

WDNW, SDNW), and is resistant to chip jamming, vibrations, and crater wear.B breaker

Enables reduced cutting force when cutting work materials such as

stainless steels, etc. that require free-cutting performance.⦿Features of insert for high-hardness materials

High-precision G-class insert suppresses dispersion in tool life.

Employs JP4105, a grade for high-hardness materials which provides long

service life for machining 50HRC or harder matrials.Features 3 Large tip diameter for excellent handling

●Compared to conventional high-feed tools, TD4N has a

large tip diameter, which suppresses the generation of

uncut remnants which easily occur on the bottom surface

of machined areas. In addition, since the cutting width

(ae) can be set to a large value, this is also effective for

improving machining efficiency.Features 4 Excellent chip discharge characteristics

●Reduces the occurrence of sudden problems due to jamming of cutting chips. In addition, good chip removal makes it possible to further improve cutting performance.

***หากต้องการขอราคาสินค้า กรุณาระบุขนาดของสินค้าที่ต้องการ เพื่อความรวดเร็วในการตอบกลับ***

-

TR4F | RADIUS MILL | MOLDINO

Radius Mill TR4F type

The new Type 15 insert added to our popular TR4F range

The definitive type for rough machining even with large molds- POINT 1 Even with interrupted cutting … High chipping resistance

- POINT 2 Even with wall face processing … Prevents scraping

- POINT 3 Even within chips … Minimized biting risk

Feature & Applications

Issue 1 Although high-feed cutting is performed for shaping, resulting severe chip clogging and biting may reduce shaping efficiency

Proposed solutions

● Adopts new body shape to enhance chip removal. Suppresses chip clogging, even when cutting long overhangs.

Point > Cutting edge designed to control chip flow

●Optimizes cutting edge design to achieve smooth chip removal flow; keeps chips away from wall surfaces.

Suppresses clogging from the time chip generation starts.

Issue 2 New equipment installed to improve the efficiency of the roughing process.

The goal is to reduce machining times with high-feed cutting. But higher feed rates reduce tool life and keep the machine from delivering its full potential.Proposed solutions

●Developed a unique insert shape. Performs stable machining despite large cutting load generated during high-feed cutting with large cross-sectional and constraint areas.

●Adopts unique unequal pitch method to reduce chattering during cutting.Point > Meets the requirements of various applications and steel types.

●The unique cross-sectional shape and cutting edge design of a single insert meets the needs of a wide range of cutting modes.

●Diverse lineup of insert grades to meet the demands posed by a wide range of work materials***หากต้องการขอราคาสินค้า กรุณาระบุขนาดของสินค้าที่ต้องการ เพื่อความรวดเร็วในการตอบกลับ***