DESCRIPTIONS

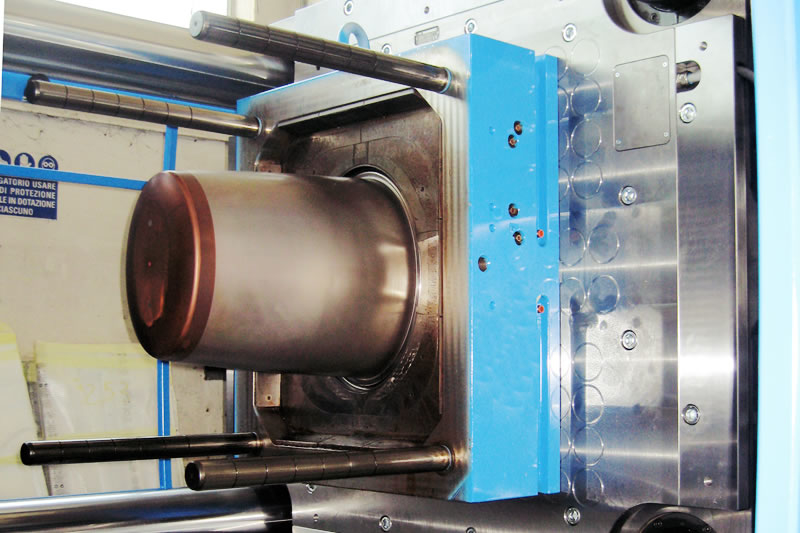

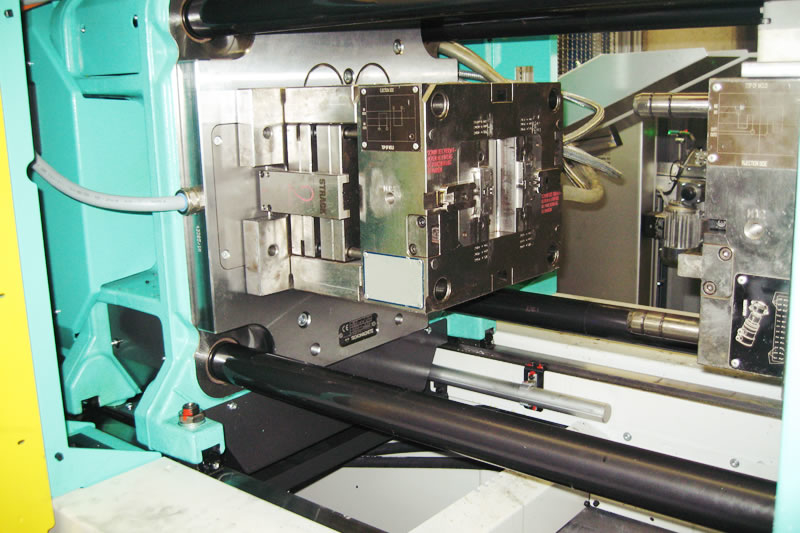

Next generation magnetic clamping

The permanent-electro PressTec system allows to works greater ease, flexibility and maximum safety on all types of injection molding machine.

PressTec guarantees dramatic increases in productivity and efficiency in JIT and SMED processes.

Highest quality

The GRIP effect generates an additional magnetic attraction ti the machine bed without affecting the magnetic force to the side of the mold, giving full uniform clamping of the mold without bending and deformation during molding operations.

• Monolithic technology

Made from a block of steel, without any fixing elements

•Permanent-electro safety

The mold remains clamped even without power supply

•Bi-directional circuit

Concentrated force and no magnetic leaks

•Neutral frame

Ejector, injectors and proximity sensors are not influenced by the magnetic field

•Grip function

A single block consisting of machine bed+magnet+mold

•Thickness 37 mm

Saves machine daylight

•Uniformity and quality of molded parts

Uniform clamping throughout the mold surface

•Quick and easy mold change

A single operator can safely complete the operation in a few minutes

•Tailor made solutions

Our know-how can meet any special need

•Advanced electronics

Operative safety to control the magnetic force