These instruments feature extremely high-speed measurement capabilities thanks to an ultra-high-precision scan motor.

They can also meet high-precision needs such as linearity precision.

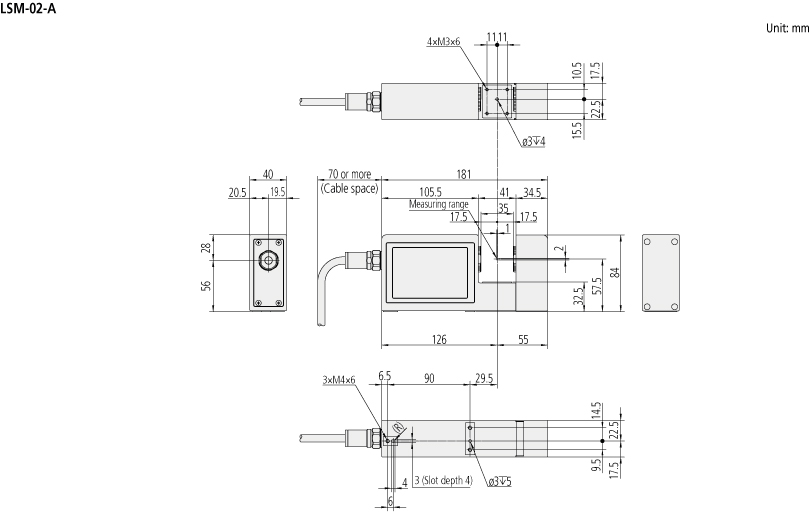

LSM-02-A

LSM sensor developed for in-line and automated equipment.

• Measuring range: 0.005 mm to 2 mm

• Guaranteed repeatability (2σ): ±0.015 μm (ø1 mm)

• Guaranteed linearity: ±0.3 μm

• Scanning rate: 3,200 scans/s

Specifications

| Order No. | 544-123 | |

| Model | LSM-02-A | |

| Measuring range | 0.005 to 2 mm 0.05 to 2 mm*¹ |

|

| Resolution | 0.01 μm | |

| Repeatability (2 σ)*² | Full range Middle range |

ø 2 mm: ± 0.03 μm*³ ø 1 mm: ± 0.015 μm*³ |

| Linearity*² | ± 0.3 μm*⁵ | |

| Positional error*²*⁷ | ± 0.4 μm | |

| Measuring region | 1 × 2 [optical axis depth] × [scanning width] mm | |

| Number of scans for averaging | 16 to 2048 scans *⁸ | |

| Laser Class | Semiconductor laser: CLASS 1 (Max. output: 1.0 mW, Laser wavelength: 650 nm) | |

| Scanning rate | 3200 scans/s | |

| Laser scanning speed | 76 m/s | |

| Protection level | IP67 | |

| Distance between the emission unit and reception unit |

- | |

| Operating environment | Temperature: 0 °C to 40 °C, Humidity: 35%RH to 85%RH (non-condensing) Altitude: 2000 m or less |

|

| Storage temperature | Temperature: -10 °C to 50 °C, Humidity: 35%RH to 85%RH (non-condensing) | |

| CE Marking / UKCA Marking | EMC Directive: EN IEC 61326-1, Immunity test requirements: Clause 6.2 Table 2 Emission limit: Class A RoHS Directive: EN IEC 63000 |

|

| Standard accessory | Signal cable: 02AGQ190 CD (User's Manual): 02AGQ039 |

|

*1 When set to "Do not perform ultra-fine wire measurement" or "Edge specification" in the basic setup.

*2 Accuracy was inspected using a glass substrate workpiece with a vapor-deposited chromium pattern.

Environment: Temperature: 20 °C±1 °C, Humidity: 50%±10 °C

*3 Value of ±2σ when a ø2 mm/ø1 mm gage is measured for two minutes at measuring intervals of 0.32 seconds (σ: standard deviation)

*4 Value of ±2σ when a ø30 mm/ø10 mm gage is measured for two minutes at measuring intervals of 0.32 seconds (σ: standard deviation)

*5 Value obtained by measurement at the middle of the measuring range

*6 ⊿D=Difference in diameter between the master gage and workpiece. (Unit: mm)

*7 Error caused by moving a workpiece either in the optical axis direction or in the scanning direction

*8 When set to "Do not perform ultra-fine wire measurement" in the basic setup, one to eight times of averaging are available within the measuring range of 0.05 mm to 2 mm.

| แบรนด์สินค้า | MITUTOYO |

|---|---|

| Order No. | 544-123 |

| Model | LSM-02-A |

| Measuring Range | 0.005 to 2 mm / 0.05 to 2 mm |

| Resolution | 0.01 μm |

| Repeatability (2 σ) | ø 2 mm: ± 0.03 μm ø 1 mm: ± 0.015 μm |

| Linearity | ± 0.3 μm |

| Positional error | ± 0.4 μm |

| Measuring region | 1 × 2 [optical axis depth] × [scanning width] mm |

| Number of scans for averaging | 16 to 2048 scans |

| Laser class | Semiconductor laser: CLASS 1 (Max. output: 1.0 mW, Laser wavelength: 650 nm) |

| Scanning rate | 3200 scans/s |

| Laser scanning speed | 76 m/s |

| Protection Level | IP67 |

| Operating environment | Temperature: 0 °C to 40 °C, Humidity: 35%RH to 85%RH (non-condensing) Altitude: 2000 m or less |

| Storage environment | Temperature: -10 °C to 50 °C, Humidity: 35%RH to 85%RH (non-condensing) |

| CE Marking / UKCA Marking | EMC Directive: EN IEC 61326-1, Immunity test requirements: Clause 6.2 Table 2 / Emission limit: Class A / RoHS Directive: EN IEC 63000 |

| Standard Accessories | Signal cable: 02AGQ190 CD (User's Manual): 02AGQ039 |