Features

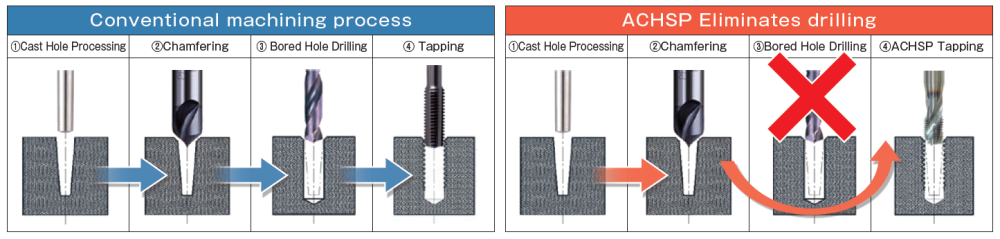

- Direct tapping of cored holes without drilling first, results in reducing the manufacturing time.

- Made from an ultrafine grain carbide alloy combining the hardness and toughness.

- The shank diameter is the same as the major diameter of the tap which improves rigidity and makes the ACHSP more

resistant to deflection and the cutting side pressure caused from misalignment. (Maximum displacement of core hole: M6 · M8 within 0.3 mm, M 10 within 0.5 mm) - A thin film coating offers improvements in wear resistance and a reduction of cutting edge chipping.

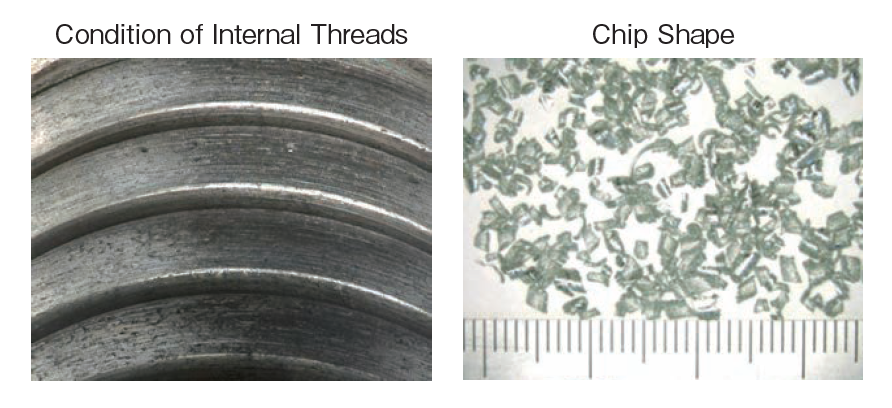

Tapping Data

Tapping Conditions [M8×1.25]

|

Workpiece Material |

ADC12 |

|

|

|

Tapping Spoeed |

50m/min |

||

|

Number of holes tapped |

50 hole |

||

|

Bored hole shape |

Bore diameter |

φ5.8 |

|

|

Taper Angle |

2° |

||

|

Depth |

22mm |

||

|

Condition |

Blind hole |

||

|

Tapping Length |

17mm |

||

|

Misalignment amount |

X direction + 0.5 mm |

||

|

Feed Type |

Synchronous feed |

||

|

Machine Type |

M / C machine (horizontal type) |

||

|

Tapping Fluid |

Water soluble cutting fluid |

||

Reduction of machining time

Correcting misaligned cast pilot holes is unnecessary shortening the tapping process time!

■Recommendation

Internal coolant supply is recommended to prevent the tapped holes from being blocked by the ejected chips.

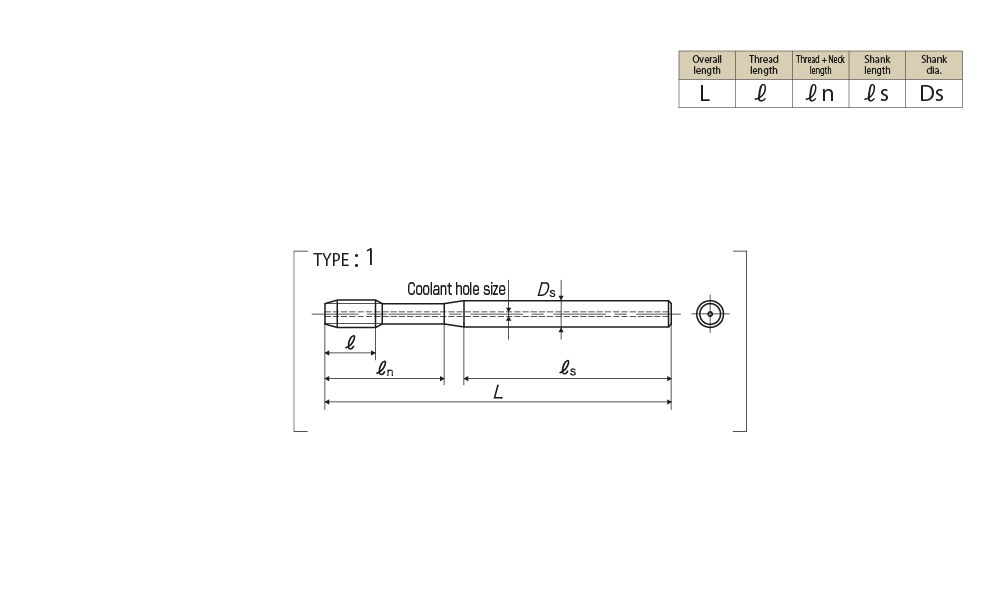

Specification

Tapping Speeds depending on Materials

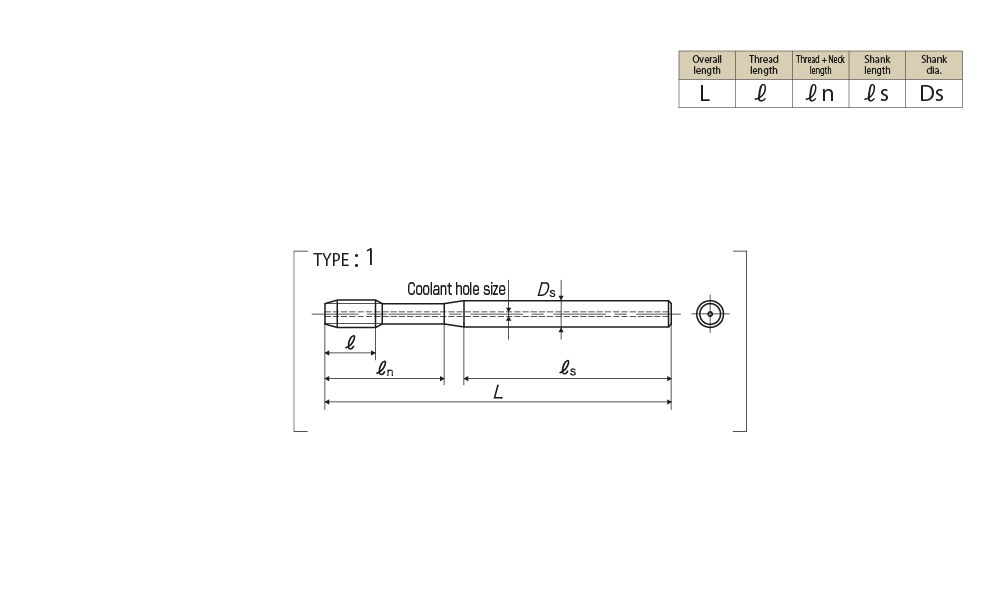

Segment:1L

|

Size |

Class |

Code |

Chamfer |

L (mm) |

ℓ (mm) |

ℓn (mm) |

ℓs (mm) |

Ds (mm) |

K (mm) |

ℓk (mm) |

No. of flutes |

Coolant hole size (mm) |

TYPE |

|

For Metric Threads |

|||||||||||||

|

M6×1 |

P3 |

SY6.0MRLXT |

2.5P |

80 |

12 |

27 |

48 |

6 |

- |

- |

3 |

1 |

1 |

|

M8×1.25 |

P4 |

SY8.0NSLXT |

2.5P |

90 |

15 |

30 |

54 |

8 |

- |

- |

3 |

1 |

1 |

|

M10×1.5 |

P4 |

SY010OSLXT |

2.5P |

100 |

18 |

36 |

57 |

10 |

- |

- |

3 |

1.5 |

1 |

|

M10×1.25 |

P4 |

SY010NSLXT |

2.5P |

100 |

18 |

36 |

57 |

10 |

- |

- |

3 |

1.5 |

1 |

| แบรนด์สินค้า | YAMAWA |

|---|---|

| Model | ACHSP |