THB 0.00

พร้อมส่ง

SKU

EGA-ujjf

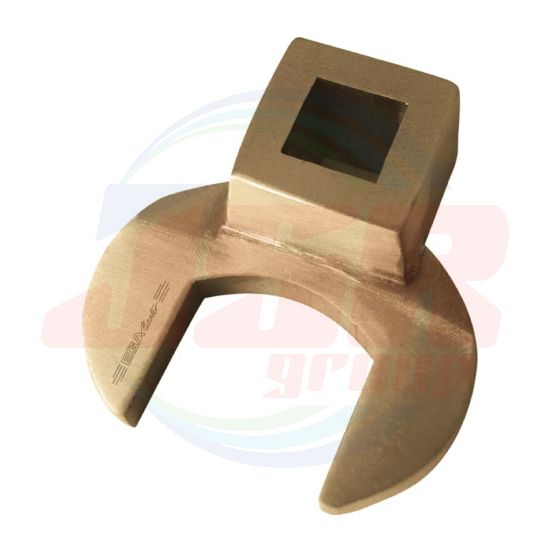

EGA Master non-sparking tools are the best alternative for applications in potentially explosive environments, providing maximum safety to the user.

1. Its open-end design allows it to be used on nuts that cannot breached with a closed-end wrench.

2. Ideal for heavy industry, shipbuilding, industrial plant maintenance and sectors where there is a risk of explosion.

3. Its hardness is 311-408 Brinell (Cu-Be) and 241-311 Brinell (Al-Bron).

| code | MAT. | AF(inch) | L(mm) | AF(inch) | g |

| 36248 | Cu-Be | 1/4 | 30 | 3/8 | 50 |

| 36249 | Al-Bron | ||||

| 35728 | Cu-Be | 3/8 | 35 | ||

| 35729 | Al-Bron | ||||

| 34814 | Cu-Be | 7/16 | |||

| 74815 | Al-Bron | ||||

| 74816 | Cu-Be | 1/2 | |||

| 74817 | Al-Bron | ||||

| 72541 | Cu-Be | 9/16 | |||

| 72542 | Al-Bron | ||||

| 72543 | Cu-Be | 5/8 | 37 | ||

| 72544 | Al-Bron | ||||

| 72545 | Cu-Be | 11/16 | 38 | ||

| 72546 | Al-Bron | ||||

| 36240 | Cu-Be | 3/4 | 40 | 55 | |

| 36241 | Al-Bron | ||||

| 72547 | Cu-Be | 7/8 | 43 | ||

| 72548 | Al-Bron | ||||

| 36242 | Cu-Be | 1 | 45 | 60 | |

| 36243 | Al-Bron | ||||

| 35862 | Cu-Be | 1.1/16 | 50 | 75 | |

| 77781 | Al-Bron | ||||

| 72549 | Cu-Be | 1.1/8 | |||

| 72550 | Al-Bron | ||||

| 72551 | Cu-Be | 1.1/4 | 55 | 90 | |

| 72552 | Al-Bron | ||||

| 78985 | Cu-Be | 1.5/16 | |||

| 78986 | Al-Bron | ||||

| 72553 | Cu-Be | 1.3/8 | |||

| 72554 | Al-Bron | ||||

| 72555 | Cu-Be | 1.1/2 | 60 | 125 | |

| 72556 | Al-Bron | ||||

| 36246 | Cu-Be | 1.5/8 | 65 | 140 | |

| 36247 | Al-Bron | ||||

| 72557 | Cu-Be | 1.11/16 | 160 | ||

| 72558 | Al-Bron | ||||

| 72559 | Cu-Be | 1.7/8 | 70 | 170 | |

| 72560 | Al-Bron | ||||

| 72561 | Cu-Be | 2 | 75 | 175 | |

| 72562 | Al-Bron | ||||

| 72563 | Cu-Be | 2.1/4 | 80 | 790 | |

| 72564 | Al-Bron |

| แบรนด์สินค้า | EGA MASTER |

|---|

เขียนรีวิวสินค้าของคุณเอง