Product Features

- IPO is the best tap for through holes to be used with lower cutting speed on drilling machines.

- Use for threading of the iron(SPC or SS400) products used in our daily life.

- Surface treated. Oxidization, the most suitable surface treatment for iron products.

- Suitable for internal thread cutting in small quantity, such as tapping of test pieces.

- Having spiral points in the chamfer portion, IPO ejects chips forward in the tapping direction and is for through hole use.

Tapping for through holes

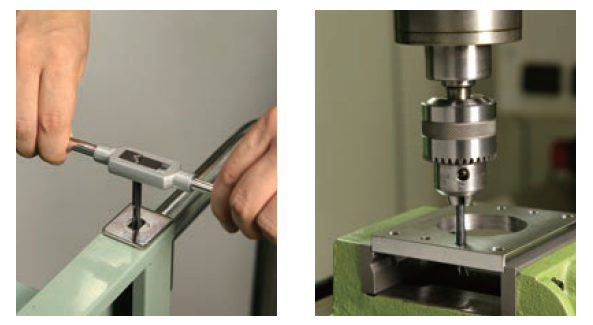

How to use IPO

- Start tapping after boring holes corresponding to the thread size by using drills.

- In the case of tapping with drilling machines, recommended tapping speed is slower than 5m/min.

- During tapping, please use tapping oil.

When hand tapping, always Machine tapping with drilling

use tap wrench machine

■Table for bored and drilled hole sizes

| Size | Minor Diameter of Internal Thread Size | Drill Size |

Thread Engagement |

||

| Minimum Tolerance |

Maximum Tolerance | ||||

| 6H (2nd Class) | 7H (3rd Class) | ||||

| M3 × 0.5 | 2.459 | 2.599 | 2.639 | 2.6(2.5) | 74%(92%) |

| M4 × 0.7 | 3.242 | 3.422 | 3.466 | 3.4(3.3) | 79%(92%) |

| M5 × 0.8 | 4.134 | 4.344 | 4.384 | 4.3(4.2) | 81%(92%) |

| M6 × 1 | 4.917 | 5.153 | 5.217 | 5.1(5.0) | 83%(92%) |

| M8 × 1.25 | 6.647 | 6.912 | 6.982 | 6.9(6.8) | 91%(89%) |

| M10 × 1.5 | 8.376 | 8.676 | 8.751 | 8.6(8.5) | 86%(92%) |

note1) Recommended drill sizes shown in this table are for internal threads of 7H class(3rd class), and are selected from the standard drills available in the

market.

note2) Drill sizes shown in brackets in this table are for such case as the drilling has oversize cutting tendency or for internal threads of 6H class(2nd class).

【Related products】

Shank adjuster

- For deep hole tappings, please use shank adjusters.

- There is only a one touch motion required to detach and attach the I series taps (IHT/ISP/IPO) from or to the shank adjuster.

*For details of shank adjuster, refer to ⑦-79

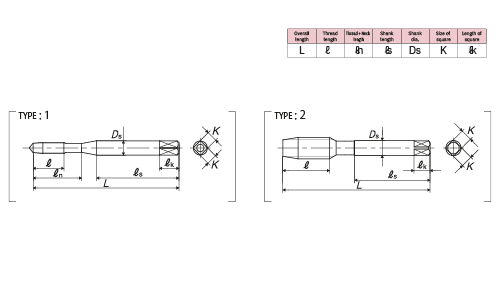

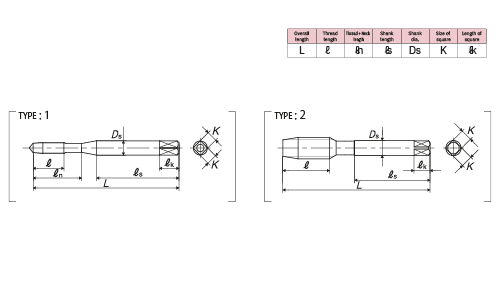

Specification

Tapping Speeds depending on Materials

Blister Pack

Segment:1E

|

Size |

Code |

Chamfer |

L (mm) |

ℓ (mm) |

ℓn (mm) |

ℓs (mm) |

Ds (mm) |

K (mm) |

ℓk (mm) |

No. of flutes |

TYPE |

|

|

For Metric Threads |

||||||||||||

|

M3×0.5 |

PI73.0GBP |

5P |

46 |

9 |

14 |

26 |

4 |

3.2 |

6 |

3 |

1 |

|

|

M4×0.7 |

PI74.0IBP |

5P |

52 |

11 |

17 |

29 |

5 |

4 |

7 |

3 |

1 |

|

|

M5×0.8 |

PI75.0KBP |

5P |

60 |

13 |

22 |

33 |

5.5 |

4.5 |

7 |

3 |

1 |

|

|

M6×1 |

PI76.0MBP |

5P |

62 |

15 |

26 |

33 |

6 |

4.5 |

7 |

3 |

1 |

|

|

M8×1.25 |

PI78.0NBP |

5P |

70 |

19 |

- |

36 |

6.2 |

5 |

8 |

3 |

2 |

|

|

M10×1.5 |

PI7010OBP |

5P |

75 |

23 |

- |

38 |

7 |

5.5 |

8 |

3 |

2 |

|

| แบรนด์สินค้า | YAMAWA |

|---|