Product Features

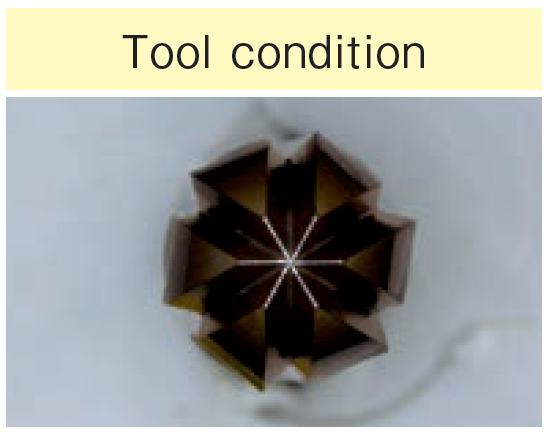

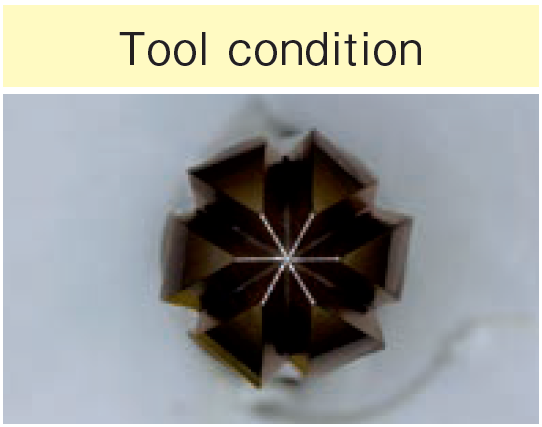

- The unique cutting edge shape is adopted so that a broken high-hardness cutting tap can be removed. The tap can be removed by drilling a hole in its center.

- Wear resistance of the tool is improved by special coating and ultra micro grain cemented carbide resistant to machining the high-hardness HSS tap

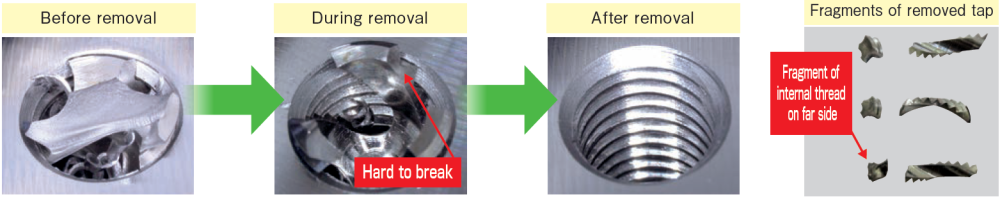

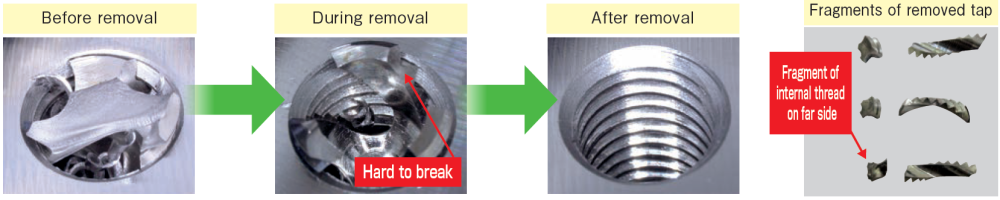

Machining case 1 (for spiral fluted taps)

Machining conditions

| Tap | SP M12×1.75 |

| Workpiece Material | S50C |

| Tool | ITRD Dc8.5 |

| Revolution Speed | 450min⁻¹ |

| Feed Speed | 3mm/min(in 0.3 mm steps) |

| Machining Depth | 15mm |

| Machine | MC BT40, vertical type |

| Cutting Fluid | Water soluble cutting fluid, (x20) |

| Internal Thread Accuracy | Gauge OK (after retapping) |

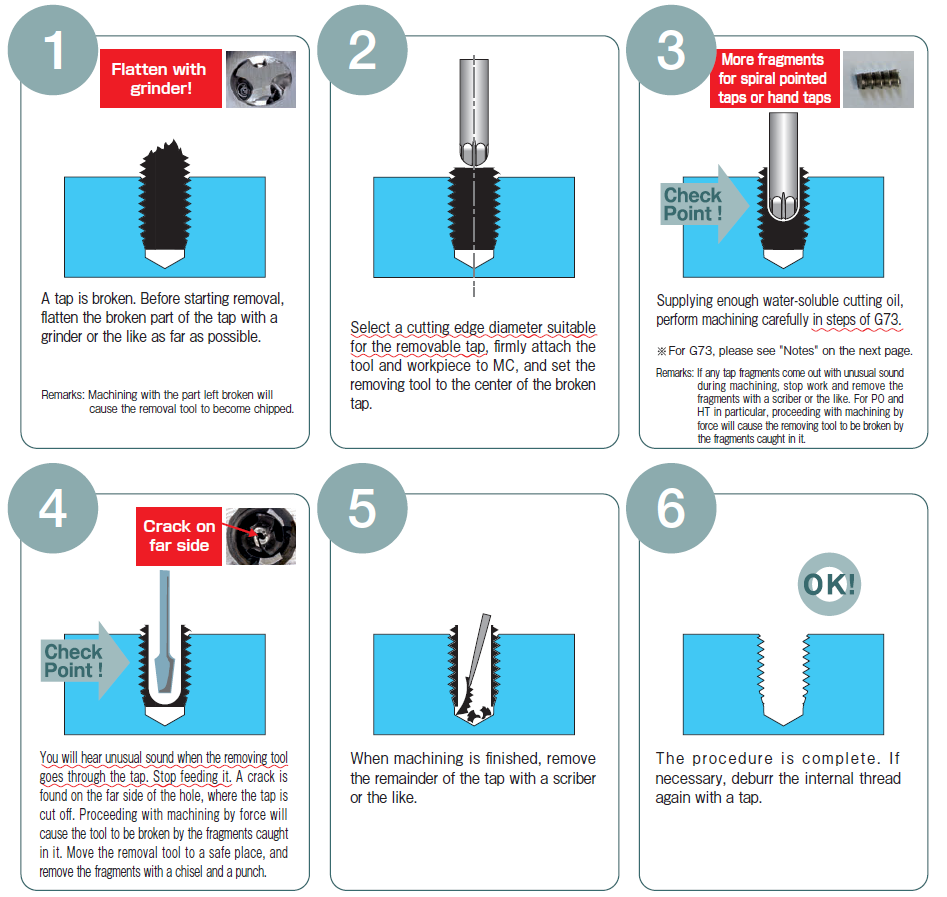

For a tap with spiral flutes, such as a spiral fluted tap, since lands of the tap are coiled around the internal thread, the tap does not move easily even during

removal a nd i ts f ragments d oes n ot c ome o ut e asily o n t he w ay. T herefore, I TRD i s m ost s uitable f or t he r emoval o f s piral f luted t aps ( 35° o r m ore o f h elix a ngle).

Machining case 2 (for hand taps or spiral pointed taps)

Machining conditions ITRD Dc-8.5

| Tap | HT M12×1.5 |

| Workpiece Material | SCM440 |

| Revolution Speed | 450min⁻¹ |

| Feed Speed | 3mm/min(in 0.3 mm steps) |

| Machining Depth | 12mm |

| Used Machine | MC, vertical type |

| Cutting Fluid | Water soluble cutting fluid, (x20) |

Remarks: For a tap with straight flutes, such as a hand tap or a spiral pointed tap, deeper machining causes lands of the tap to bend more easily, and its fragments to come out easily. Therefore, if any tap fragments come out with unusual sound during removal, stop machining and remove the fragments with a scriber or the like. While doing so, proceed with machining carefully.

Removable taps and machining conditions

| Cutting Edge Dia. Dc (mm) |

Removable Tap | Revolution Speed (min⁻¹) |

Feed Speed (mm/min) |

G73 |

||

| SP | PO | HT | ||||

| 6.0 | M8・M10 | M8 | M10 | 550 ~ 650 | 2~4 | 0.2~0.4 |

| 7.0 | M8・M10 | M10 | M12 | 550 ~ 650 | ||

| 8.5 | M12・M14・M16 | M12 | M12•M14 | 400 ~ 500 | ||

・ This is most suitable for the removal of spiral fluted taps (with helix angle of 35° or more).

Please see“ Machining case 1” <for spiral fluted taps> on the pre-page.

Removal procedure

・To eject sludge during machining, water-soluble cutting oil is recommended.

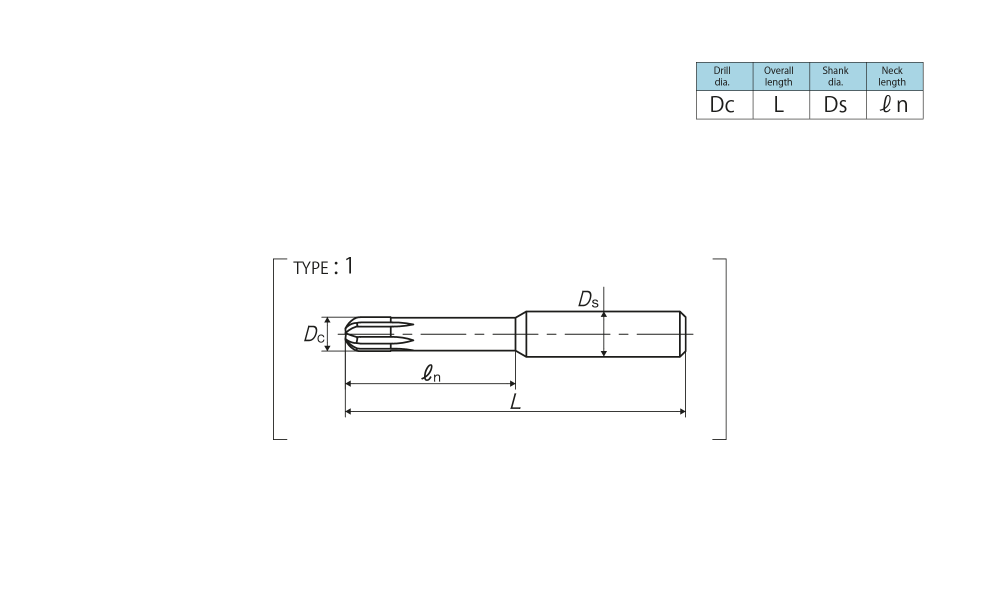

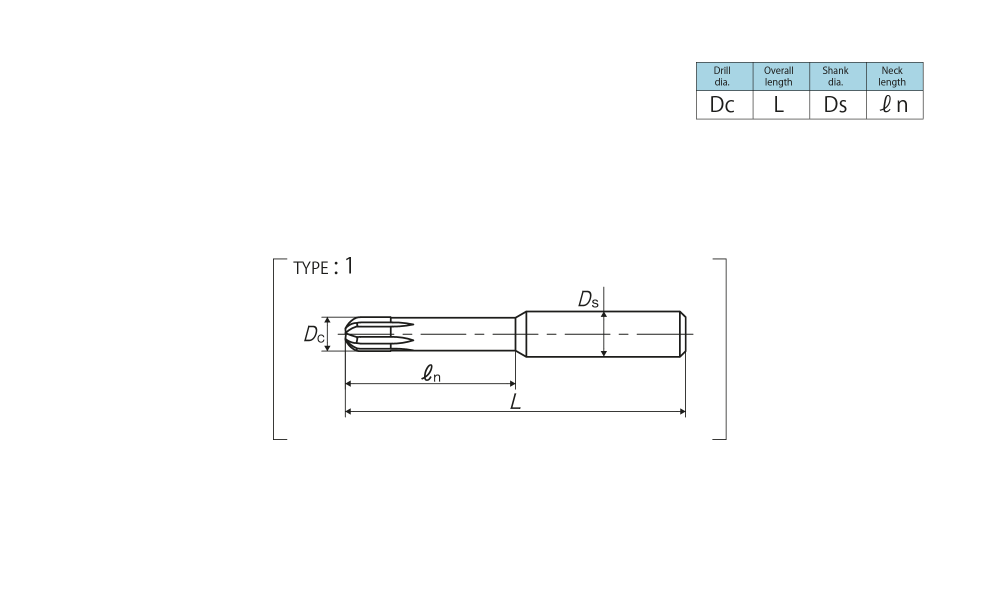

Specification

Segment:52

|

Size Dc × Ds ×L |

Code |

Dc (mm) |

L (mm) |

Ds (mm) |

ℓn (mm) |

TYPE |

|

For Metric Threads |

||||||

|

6×8×60 |

ITZ6.00ZPWSI |

6 |

60 |

8 |

30 |

1 |

|

7×8×70 |

ITZ7.00ZPWSI |

7 |

70 |

8 |

35 |

1 |

|

8.5×10×75 |

ITZ8.50ZPWSJ |

8.5 |

75 |

10 |

40 |

1 |

Notes

① Compatible machines include vertical type MC, NC, and milling machines. It cannot be used with a drilling machine.

② The depth of the tap to remove is 1.5D or less for spiral fluted taps or 1D or less for spiral pointed taps and hand taps.

③ Use a machine and tooling that have high stiffness. In addition, supply enough water-soluble cutting oil.

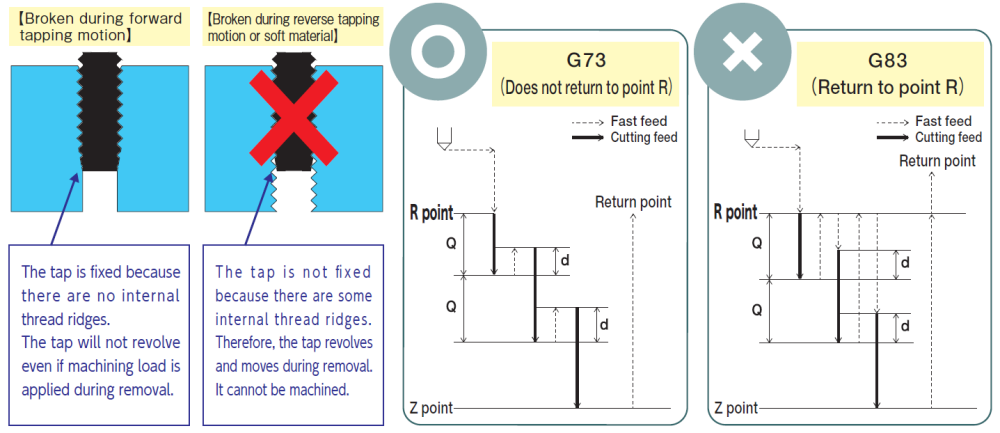

④ Although it is possible to remove a tap broken in forward tapping, ITRD cannot remove a tap broken in reverse tapping because

the tap revolves and moves during removal.

⑤ The recommended material of workpiece is steel, which is high in cutting torque. For a soft material, such as aluminum,

it is not possible to remove because the tap revolves and moves during removal.

Remarks: The internal threads may be broken after using the ITRD. Therefore, there is no guarantee of the internal thread quality after the tap removal.

| แบรนด์สินค้า | YAMAWA |

|---|