Product Features

- The same PRML TI can process right and left hand internal threads by using the helical interpolating process.

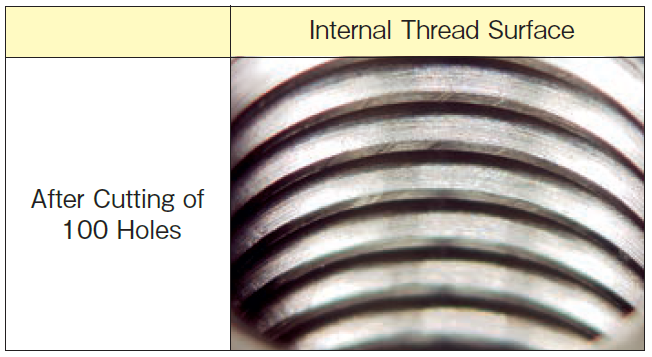

- This is most suitable for tapping heat-resistant alloys.

- Because it cuts at the first thread, it won't make the internal threads taper and the internal threads become

highly accurate. - When cutting, the load on the tool is small and the tool life is long.

- Cutting resistance is reduced by turning the tool counterclockwise and machining it from the top to the bottom with 1 pass cutting.

Cutting Data

Processing Conditions[6.0P1.0]

| Workpiece Material | Ti-6Aℓ-4V |  |

|

| Cutting Speed | 50m/min | ||

| Feed per Tooth | 0.04mm/t | ||

| Cutting Length | 10mm | ||

| Bored Hole Size | φ7.0 | ||

| Number of Passes | 1Time | ||

| Machinery Type | Machining center(BT30) | ||

| Cutting Fluid | Water soluble cutting fluid, 20 to 1 dilution | ||

Instructions

Use a counterclockwise spindle rotation for a left hand

cutting tool. Process from top to the bottom like ② 〜 ③.

The program can be created from our web site.

Processing Conditions:

| Workpiece Material | Cutting Speed (m/min) |

Feed per Tooth fz (mm/t) |

| Titanium Alloy | 40 ~ 60 | 0.02 ~ 0.06 |

| Austenitic Stainless Steel | 60 ~ 80 | 0.06 ~ 0.08 |

| Martensitic Stainless Steel | 40 ~ 60 | 0.02 ~ 0.06 |

1) These cutting conditions are based on water soluble cutting fluid.

Depending on the condition of the cutting fluid, satisfactory performance

may not be delivered.

2) Being careful of the nozzle position, supply enough oil obliquely from

above the tool during use.

・ Formulas for revolution speed and feed speed of tool

Revolution speed (min-1) = 1000 x Cutting speed / 3.14 / Cutter dia. (Dc)

Feed speed (mm/min) = fz x No. of flutes x Revolution speed x (Nominal dia. of

internal thread - Cutter dia. (Dc)) / Nominal dia. of internal thread

Specification

Tapping Speeds depending on Materials

Segment:1L

|

Tool No. |

Code |

Dc (mm) |

Pitch (mm) |

L (mm) |

ℓ (mm) |

ℓn (mm) |

Ds (mm) |

No. of flutes |

Min. size |

Max. threading length |

TYPE |

|

For Metric Threads |

|||||||||||

|

1.5P0.4 |

MH1.5ENIWLM |

1.5 |

0.4 |

50 |

1.2 |

5.2 |

4 |

3 |

2 |

4 |

1 |

|

1.7P0.45 |

MH1.7FNIWLM |

1.7 |

0.45 |

50 |

1.4 |

5.8 |

4 |

3 |

2.2 |

4.4 |

1 |

|

2.4P0.5 |

MH2.4GNIWLM |

2.4 |

0.5 |

50 |

1.5 |

7.5 |

4 |

3 |

3 |

6 |

1 |

|

3.1P0.7 |

MH3.1INIWLM |

3.1 |

0.7 |

50 |

2.1 |

10.1 |

4 |

3 |

4 |

8 |

1 |

|

3.5P0.8 |

MH3.5KNIWLM |

3.5 |

0.8 |

60 |

2.4 |

12 |

6 |

3 |

5 |

10 |

1 |

|

4.0P1.0 |

MH4.0MNIWLM |

4.0 |

1 |

60 |

3 |

14 |

6 |

3 |

6 |

12 |

1 |

|

4.0P0.75 |

MH4.0JNIWLM |

4.0 |

0.75 |

60 |

2.3 |

14 |

6 |

3 |

6 |

12 |

1 |

|

6.0P1.25 |

MH6.0NNIWLM |

6 |

1.25 |

70 |

3.8 |

18 |

6 |

4 |

8 |

16 |

1 |

|

6.0P1.0 |

MH6.0MNIWLM |

6 |

1 |

70 |

3 |

18 |

6 |

4 |

8 |

16 |

1 |

|

7.5P1.5 |

MH7.5ONIWLM |

7.5 |

1.5 |

80 |

4.5 |

22 |

8 |

4 |

10 |

20 |

1 |

|

7.5P1.25 |

MH7.5NNIWLM |

7.5 |

1.25 |

80 |

3.8 |

22 |

8 |

4 |

10 |

20 |

1 |

|

7.5P1.0 |

MH7.5MNIWLM |

7.5 |

1 |

80 |

3 |

22 |

8 |

4 |

10 |

20 |

1 |

|

9.0P1.75 |

MH9.0PNIWLM |

9 |

1.75 |

90 |

5.3 |

26 |

10 |

4 |

12 |

24 |

1 |

|

9.0P1.5 |

MH9.0ONIWLM |

9 |

1.5 |

90 |

4.5 |

26 |

10 |

4 |

12 |

24 |

1 |

|

9.0P1.25 |

MH9.0NNIWLM |

9 |

1.25 |

90 |

3.8 |

26 |

10 |

4 |

12 |

24 |

1 |

| แบรนด์สินค้า | YAMAWA |

|---|