Setting Rings SERIES 177 — Accessories for Inside Micrometers, Holtest and Dial Bore Gages | MITUTOYO

ราคาต่ำสุด

THB 0.00

ราคาปรกติ

THB 2,471.96

พร้อมส่ง

SKU

SETTING-RING

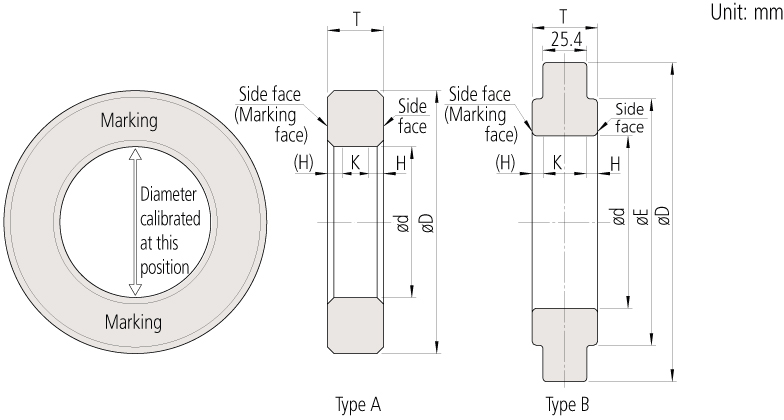

• Used for quick and accurate setting of dial bore gages, Holtest, and inside micrometers.

• Actual diameter is marked in 0.001 mm increments. (Measuring position of dimension is the center of the height T.)

Steel Setting Rings

Metric

| Order No. | Nominal size ød (mm) |

Dimensions (mm) | Type | Accuracy | ||||||

| øD | øE | T | Tolerance between the nominal size and the actual diameter (μm) |

Uncertainty of marked diameter value*1 (μm) |

Roundness / Cylindricity*2 (μm) |

Distance from the side face H (mm) |

Size of warranted calibration surface K (mm) |

|||

| 177-220 | 1 | 20 | - | 4 | A | ±10 | 1.5 | 1.0 | 1.6 | 0.8 |

| 177-222 | 1.1 | 20 | - | 4 | A | ±10 | 1.5 | 1.0 | 1.6 | 0.8 |

| 177-225 | 1.2 | 20 | - | 4 | A | ±10 | 1.5 | 1.0 | 1.6 | 0.8 |

| 177-227 | 1.3 | 20 | - | 4 | A | ±10 | 1.5 | 1.0 | 1.6 | 0.8 |

| 177-230 | 1.4 | 20 | - | 4 | A | ±10 | 1.5 | 1.0 | 1.6 | 0.8 |

| 177-236 | 1.75 | 25 | - | 5 | A | ±10 | 1.5 | 1.0 | 1.6 | 1.8 |

| 177-239 | 2 | 25 | - | 5 | A | ±10 | 1.5 | 1.0 | 1.6 | 1.8 |

| 177-242 | 2.25 | 25 | - | 5 | A | ±10 | 1.5 | 1.0 | 1.6 | 1.8 |

| 177-208 | 2.5 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.6 | 3.6 |

| 177-246 | 2.75 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-248 | 3 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-250 | 3.25 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-252 | 3.5 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-255 | 3.75 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-204 | 4 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-257 | 4.5 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-205 | 5 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-263 | 5.5 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-267 | 6 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-271 | 6.5 | 25 | - | 7 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-275 | 7 | 25 | - | 10 | A | ±10 | 1.5 | 1.0 | 1.7 | 3.6 |

| 177-125 | 8 | 32 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-279 | 9 | 32 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-126 | 10 | 32 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-284 | 12 | 32 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-132 | 14 | 38 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-177 | 16 | 45 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-133 | 17 | 45 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-285 | 18 | 45 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-286 | 20 | 45 | - | 10 | A | ±10 | 1.5 | 1.0 | 2.0 | 6.0 |

| 177-139 | 25 | 53 | - | 15 | A | ±10 | 1.5 | 1.0 | 3.2 | 8.6 |

| 177-288 | 30 | 71 | - | 15 | A | ±10 | 1.5 | 1.0 | 3.2 | 8.6 |

| 177-140 | 35 | 71 | - | 15 | A | ±10 | 1.5 | 1.0 | 3.2 | 8.6 |

| 177-290 | 40 | 71 | - | 15 | A | ±10 | 1.5 | 1.0 | 3.2 | 8.6 |

| 177-178 | 45 | 85 | - | 15 | A | ±10 | 1.5 | 1.0 | 3.7 | 7.6 |

| 177-146 | 50 | 85 | - | 20 | A | ±20 | 1.5 | 1.0 | 3.7 | 12.6 |

| 177-292 | 60 | 112 | - | 20 | A | ±20 | 1.5 | 1.0 | 3.7 | 12.6 |

| 177-314 | 62 | 112 | - | 20 | A | ±20 | 1.5 | 1.5 | 3.7 | 12.6 |

| 177-147 | 70 | 112 | - | 20 | A | ±20 | 1.5 | 1.5 | 3.7 | 12.6 |

| 177-316 | 75 | 125 | - | 25 | A | ±20 | 1.5 | 1.5 | 4.2 | 16.6 |

| 177-294 | 80 | 125 | - | 25 | A | ±20 | 1.5 | 1.5 | 4.2 | 16.6 |

| 177-318 | 87 | 140 | - | 25 | A | ±20 | 1.5 | 1.5 | 4.2 | 16.6 |

| 177-148 | 90 | 140 | - | 25 | A | ±20 | 1.5 | 1.5 | 4.2 | 16.6 |

| 177-296 | 100 | 160 | - | 25 | A | ±20 | 1.5 | 2.0 | 4.2 | 16.6 |

| 177-298 | 125 | 210 | 168 | 38.1 (25.4) |

B | ±20 | 2.5 | 2.0 | 5.3 | 27.5 |

| 177-300 | 150 | 235 | 187 | B | ±20 | 2.5 | 2.0 | 5.3 | 27.5 | |

| 177-302 | 175 | 260 | 215 | B | ±20 | 2.5 | 2.5 | 5.3 | 27.5 | |

| 177-304 | 200 | 311 | 244 | B | ±20 | 2.5 | 2.5 | 5.3 | 27.5 | |

| 177-306 | 225 | 337 | 264 | B | ±20 | 2.5 | 2.5 | 5.3 | 27.5 | |

| 177-308 | 250 | 362 | 290 | B | ±20 | 2.5 | 3.0 | 5.3 | 27.5 | |

| 177-310 | 275 | 413 | 321 | B | ±20 | 2.5 | 3.0 | 5.3 | 27.5 | |

| 177-312 | 300 | 438 | 340 | B | ±20 | 2.5 | 3.0 | 5.3 | 27.5 | |

*1 Actual diameter is marked in 0.001 mm increments. (Dimension measuring position is the center of the height T.)

*2 Cylindricity is defined as per JIS B 0621 Definitions and designations of geometrical deviations, Section 4.4 “Cylindricity.” Cylindricity is measured using three cross-sections between the top and bottom face of a ring, namely, close to the face near each side and the center.

| แบรนด์สินค้า | MITUTOYO |

|---|

เขียนรีวิวสินค้าของคุณเอง