- Specification of SIT is available up to M48 (U1 3/4). For details, please contact us.

Product Features

- SIT is a simple thread inspection tool that allows you to easily check internal threads on your production line.

- The blue color is used to indicate "GO", while the red color is used for "Not Go" for easy identification and storage.

- Utilizing a high grade of HSS material, the gauge life has increased significantly.

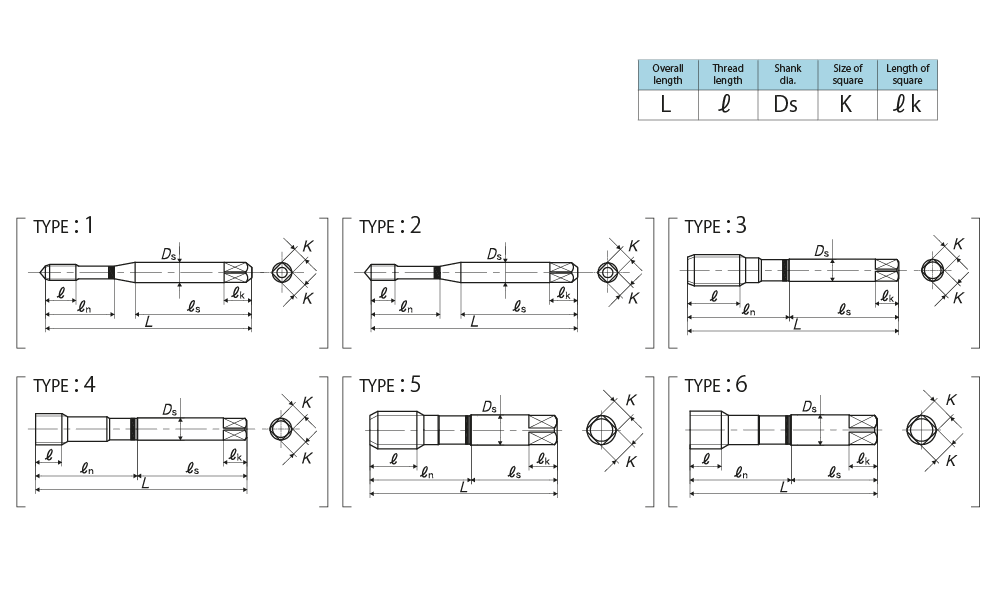

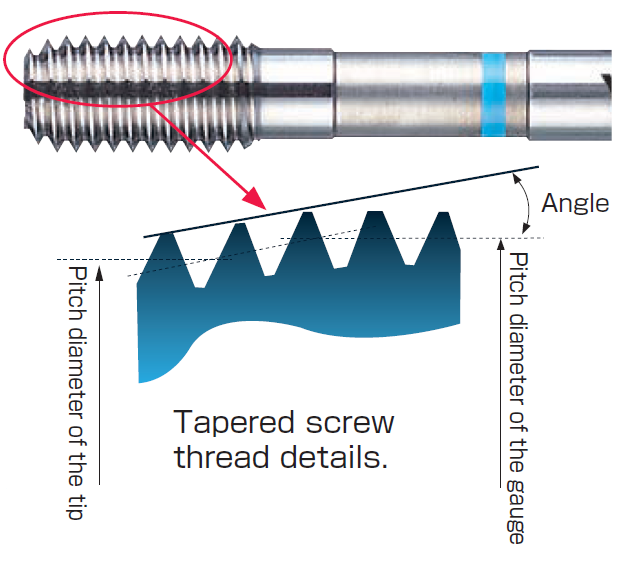

- By using a stepped threads or tapered threads design at the front end of screw thread section, the problems in inspection were reduced while the work efficiency was improved. The tip of SIT gauge is easy to insert into an internal screw thread as the thread height gradually becomes larger. This is particularly effective when inspecting fine pitch threads.

- Note: Stepped threaded design is not used for "Not Go".

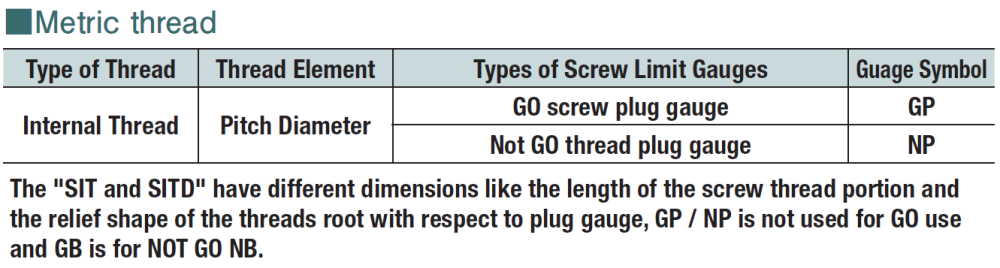

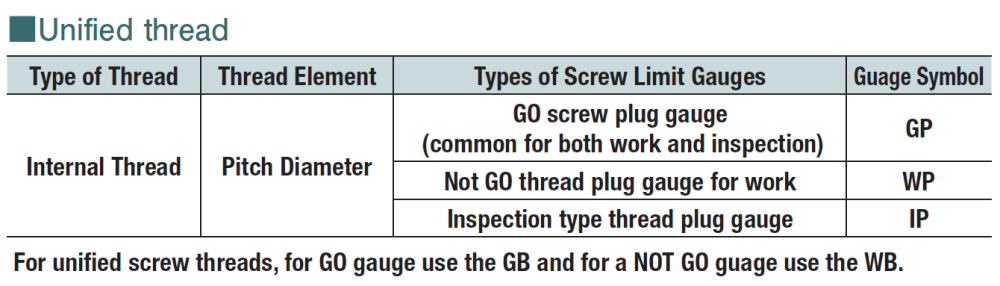

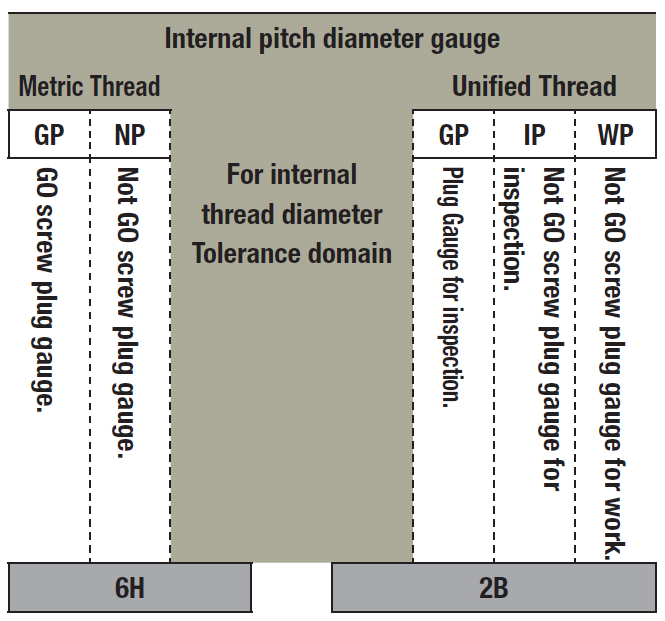

Go and Not Go notations

- SIT notations are as follows: GB (metric screw threads and unified screw threads) for GO, and NB (metric screw threads) and WB (unified screw threads) for NOT GO.

These notations conform to the "gauge symbol" of JIS standards.

Both metric screw threads and unified screw threads are manufactured in accordance with JIS standards. For a reference point: the metric screw threads have been specified to be consistent with ISO while the unified screw threads have been specified as it was before the introduction of ANSI standard.

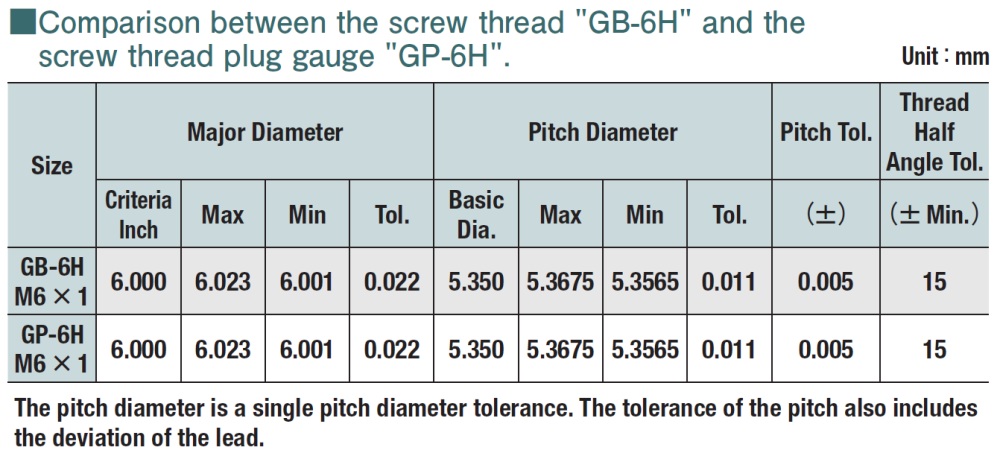

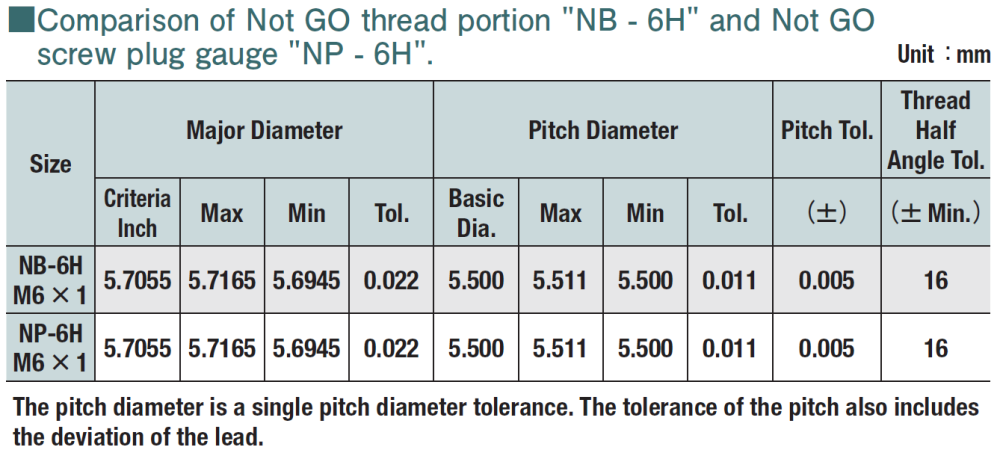

Accuracy of SIT

The single pitch diameter tolerance, the thread pitch tolerance and the threads half angle tolerance are important in the internal thread accuracy measurement and are manufactured using the same accuracy of JIS-compliant thread plug gauges.

The screw thread precision is the same as a thread gauge, but some of the specifications like length of screw thread portion and the relief shape of the thread root are originated by YAMAWA. Therefore, these gauges are not to be called "thread gauge" and distinguished as "simple inspection tools for internal screw threads".

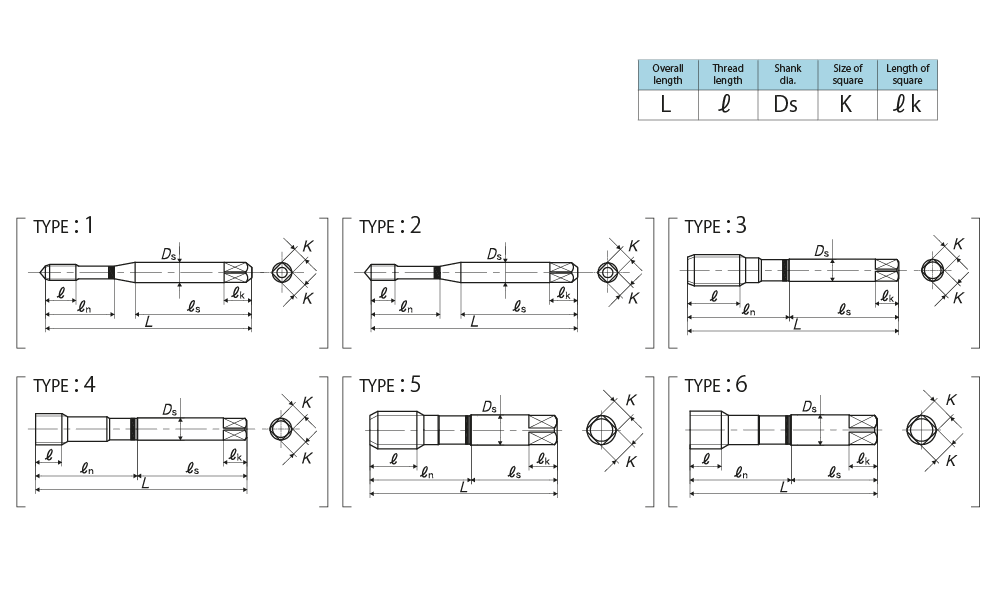

Specification

Segment:7B

|

Size |

Class |

Code |

L (mm) |

ℓ (mm) |

ℓn (mm) |

ℓs (mm) |

Ds (mm) |

K (mm) |

ℓk (mm) |

TYPE |

|

|

For Metric Threads |

|||||||||||

|

M2×0.4 |

GB |

6H |

ITM62.0EG |

42 |

5.5 |

12 |

27 |

3 |

2.5 |

5 |

1 |

|

M2×0.4 |

NB |

6H |

ITM62.0EN |

42 |

4.5 |

12 |

27 |

3 |

2.5 |

5 |

2 |

|

M2×0.25 |

GB |

5H |

ITM52.0BG |

42 |

4 |

12 |

27 |

3 |

2.5 |

5 |

1 |

|

M2×0.25 |

NB |

5H |

ITM52.0BN |

42 |

3.5 |

12 |

27 |

3 |

2.5 |

5 |

2 |

|

M2.2×0.45 |

GB |

6H |

ITM62.2FG |

42 |

5.5 |

12 |

27 |

3 |

2.5 |

5 |

1 |

|

M2.2×0.45 |

NB |

6H |

ITM62.2FN |

42 |

4.5 |

12 |

27 |

3 |

2.5 |

5 |

2 |

|

M2.2×0.25 |

GB |

5H |

ITM52.2BG |

42 |

4 |

12 |

27 |

3 |

2.5 |

5 |

1 |

|

M2.2×0.25 |

NB |

5H |

ITM52.2BN |

42 |

3.5 |

12 |

27 |

3 |

2.5 |

5 |

2 |

|

M2.3×0.4 |

GB |

6H |

ITM62.3EG |

42 |

5.5 |

12 |

27 |

3 |

2.5 |

5 |

1 |

|

M2.3×0.4 |

NB |

6H |

ITM62.3EN |

42 |

4.5 |

12 |

27 |

3 |

2.5 |

5 |

2 |

|

M2.3×0.25 |

GB |

5H |

ITM52.3BG |

42 |

4 |

12 |

27 |

3 |

2.5 |

5 |

1 |

|

M2.3×0.25 |

NB |

5H |

ITM52.3BN |

42 |

3.5 |

12 |

27 |

3 |

2.5 |

5 |

2 |

|

M2.5×0.45 |

GB |

6H |

ITM62.5FG |

46 |

5.5 |

14 |

29 |

3 |

2.5 |

5 |

1 |

|

M2.5×0.45 |

NB |

6H |

ITM62.5FN |

46 |

4.5 |

14 |

29 |

3 |

2.5 |

5 |

2 |

|

M2.5×0.35 |

GB |

6H |

ITM62.5DG |

46 |

4.5 |

14 |

29 |

3 |

2.5 |

5 |

1 |

|

M2.5×0.35 |

NB |

6H |

ITM62.5DN |

46 |

3.5 |

14 |

29 |

3 |

2.5 |

5 |

2 |

|

M2.6×0.45 |

GB |

6H |

ITM62.6FG |

46 |

5.5 |

14 |

29 |

3 |

2.5 |

5 |

1 |

|

M2.6×0.45 |

NB |

6H |

ITM62.6FN |

46 |

4.5 |

14 |

29 |

3 |

2.5 |

5 |

2 |

|

M2.6×0.35 |

GB |

6H |

ITM62.6DG |

46 |

4.5 |

14 |

29 |

3 |

2.5 |

5 |

1 |

|

M2.6×0.35 |

NB |

6H |

ITM62.6DN |

46 |

3.5 |

14 |

29 |

3 |

2.5 |

5 |

2 |

|

M3×0.5 |

GB |

6H |

ITM63.0GG |

46 |

5.5 |

14 |

26 |

4 |

3.2 |

6 |

1 |

|

M3×0.5 |

NB |

6H |

ITM63.0GN |

46 |

4.5 |

14 |

26 |

4 |

3.2 |

6 |

2 |

|

M3×0.35 |

GB |

6H |

ITM63.0DG |

46 |

4.5 |

14 |

26 |

4 |

3.2 |

6 |

1 |

|

M3×0.35 |

NB |

6H |

ITM63.0DN |

46 |

3.5 |

14 |

26 |

4 |

3.2 |

6 |

2 |

|

M3.5×0.6 |

GB |

6H |

ITM63.5HG |

52 |

7.5 |

16 |

29 |

5 |

4 |

7 |

1 |

|

M3.5×0.6 |

NB |

6H |

ITM63.5HN |

52 |

6 |

16 |

29 |

5 |

4 |

7 |

2 |

|

M3.5×0.35 |

GB |

6H |

ITM63.5DG |

52 |

4.5 |

16 |

29 |

5 |

4 |

7 |

1 |

|

M3.5×0.35 |

NB |

6H |

ITM63.5DN |

52 |

3.5 |

16 |

29 |

5 |

4 |

7 |

2 |

|

M4×0.7 |

GB |

6H |

ITM64.0IG |

52 |

7.5 |

17 |

29 |

5 |

4 |

7 |

1 |

|

M4×0.7 |

NB |

6H |

ITM64.0IN |

52 |

6 |

17 |

29 |

5 |

4 |

7 |

2 |

|

M4×0.5 |

GB |

6H |

ITM64.0GG |

52 |

7.5 |

17 |

29 |

5 |

4 |

7 |

1 |

|

M4×0.5 |

NB |

6H |

ITM64.0GN |

52 |

6 |

17 |

29 |

5 |

4 |

7 |

2 |

|

M4.5×0.75 |

GB |

6H |

ITM64.5JG |

60 |

7.5 |

21 |

33 |

5.5 |

4.5 |

7 |

1 |

|

M4.5×0.75 |

NB |

6H |

ITM64.5JN |

60 |

6 |

21 |

33 |

5.5 |

4.5 |

7 |

2 |

|

M4.5×0.5 |

GB |

6H |

ITM64.5GG |

60 |

7.5 |

21 |

33 |

5.5 |

4.5 |

7 |

1 |

|

M4.5×0.5 |

NB |

6H |

ITM64.5GN |

60 |

6 |

21 |

33 |

5.5 |

4.5 |

7 |

2 |

|

M5×0.8 |

GB |

6H |

ITM65.0KG |

60 |

10 |

22 |

33 |

5.5 |

4.5 |

7 |

1 |

|

M5×0.8 |

NB |

6H |

ITM65.0KN |

60 |

6 |

22 |

33 |

5.5 |

4.5 |

7 |

2 |

|

M5×0.5 |

GB |

6H |

ITM65.0GG |

60 |

7 |

22 |

33 |

5.5 |

4.5 |

7 |

1 |

|

M5×0.5 |

NB |

6H |

ITM65.0GN |

60 |

6 |

22 |

33 |

5.5 |

4.5 |

7 |

2 |

|

M5.5×0.5 |

GB |

6H |

ITM65.5GG |

62 |

7 |

26 |

33 |

6 |

4.5 |

7 |

1 |

|

M5.5×0.5 |

NB |

6H |

ITM65.5GN |

62 |

6 |

26 |

33 |

6 |

4.5 |

7 |

2 |

|

M6×1 |

GB |

6H |

ITM66.0MG |

62 |

10 |

26 |

33 |

6 |

4.5 |

7 |

1 |

|

M6×1 |

NB |

6H |

ITM66.0MN |

62 |

6 |

26 |

33 |

6 |

4.5 |

7 |

2 |

|

M6×0.75 |

GB |

6H |

ITM66.0JG |

62 |

7.5 |

26 |

33 |

6 |

4.5 |

7 |

1 |

|

M6×0.75 |

NB |

6H |

ITM66.0JN |

62 |

6 |

26 |

33 |

6 |

4.5 |

7 |

2 |

|

M7×1 |

GB |

6H |

ITM67.0MG |

70 |

12 |

34 |

36 |

6.2 |

5 |

8 |

3 |

|

M7×1 |

NB |

6H |

ITM67.0MN |

70 |

6 |

34 |

36 |

6.2 |

5 |

8 |

4 |

|

M7×0.75 |

GB |

6H |

ITM67.0JG |

70 |

9 |

34 |

36 |

6.2 |

5 |

8 |

3 |

|

M7×0.75 |

NB |

6H |

ITM67.0JN |

70 |

6 |

34 |

36 |

6.2 |

5 |

8 |

4 |

|

M8×1.25 |

GB |

6H |

ITM68.0NG |

70 |

15 |

34 |

36 |

6.2 |

5 |

8 |

3 |

|

M8×1.25 |

NB |

6H |

ITM68.0NN |

70 |

10 |

34 |

36 |

6.2 |

5 |

8 |

4 |

|

M8×1 |

GB |

6H |

ITM68.0MG |

70 |

12 |

34 |

36 |

6.2 |

5 |

8 |

3 |

|

M8×1 |

NB |

6H |

ITM68.0MN |

70 |

6 |

34 |

36 |

6.2 |

5 |

8 |

4 |

|

M8×0.75 |

GB |

6H |

ITM68.0JG |

70 |

9 |

34 |

36 |

6.2 |

5 |

8 |

3 |

|

M8×0.75 |

NB |

6H |

ITM68.0JN |

70 |

6 |

34 |

36 |

6.2 |

5 |

8 |

4 |

|

M9×1.25 |

GB |

6H |

ITM69.0NG |

75 |

15 |

37 |

38 |

7 |

5.5 |

8 |

3 |

|

M9×1.25 |

NB |

6H |

ITM69.0NN |

75 |

10 |

37 |

38 |

7 |

5.5 |

8 |

4 |

|

M9×1 |

GB |

6H |

ITM69.0MG |

75 |

12 |

37 |

38 |

7 |

5.5 |

8 |

3 |

|

M9×1 |

NB |

6H |

ITM69.0MN |

75 |

6 |

37 |

38 |

7 |

5.5 |

8 |

4 |

|

M9×0.75 |

GB |

6H |

ITM69.0JG |

75 |

9 |

37 |

38 |

7 |

5.5 |

8 |

3 |

|

M9×0.75 |

NB |

6H |

ITM69.0JN |

75 |

6 |

37 |

38 |

7 |

5.5 |

8 |

4 |

|

M10×1.5 |

GB |

6H |

ITM6010OG |

75 |

15 |

37 |

38 |

7 |

5.5 |

8 |

3 |

|

M10×1.5 |

NB |

6H |

ITM6010ON |

75 |

10 |

37 |

38 |

7 |

5.5 |

8 |

4 |

|

M10×1.25 |

GB |

6H |

ITM6010NG |

75 |

15 |

37 |

38 |

7 |

5.5 |

8 |

3 |

|

M10×1.25 |

NB |

6H |

ITM6010NN |

75 |

10 |

37 |

38 |

7 |

5.5 |

8 |

4 |

|

M10×1 |

GB |

6H |

ITM6010MG |

75 |

12 |

37 |

38 |

7 |

5.5 |

8 |

3 |

|

M10×1 |

NB |

6H |

ITM6010MN |

75 |

6 |

37 |

38 |

7 |

5.5 |

8 |

4 |

|

M10×0.75 |

GB |

6H |

ITM6010JG |

75 |

9 |

37 |

38 |

7 |

5.5 |

8 |

3 |

|

M10×0.75 |

NB |

6H |

ITM6010JN |

75 |

6 |

37 |

38 |

7 |

5.5 |

8 |

4 |

|

M11×1.5 |

GB |

6H |

ITM6011OG |

82 |

19 |

40 |

42 |

8.5 |

6.5 |

9 |

3 |

|

M11×1.5 |

NB |

6H |

ITM6011ON |

82 |

10 |

40 |

42 |

8.5 |

6.5 |

9 |

4 |

|

M11×1 |

GB |

6H |

ITM6011MG |

82 |

12 |

40 |

42 |

8.5 |

6.5 |

9 |

3 |

|

M11×1 |

NB |

6H |

ITM6011MN |

82 |

6 |

40 |

42 |

8.5 |

6.5 |

9 |

4 |

|

M11×0.75 |

GB |

6H |

ITM6011JG |

82 |

10 |

40 |

42 |

8.5 |

6.5 |

9 |

3 |

|

M11×0.75 |

NB |

6H |

ITM6011JN |

82 |

6 |

40 |

42 |

8.5 |

6.5 |

9 |

4 |

|

M12×1.75 |

GB |

6H |

ITM6012PG |

82 |

20 |

40 |

42 |

8.5 |

6.5 |

9 |

3 |

|

M12×1.75 |

NB |

6H |

ITM6012PN |

82 |

10 |

40 |

42 |

8.5 |

6.5 |

9 |

4 |

|

M12×1.5 |

GB |

6H |

ITM6012OG |

82 |

20 |

40 |

42 |

8.5 |

6.5 |

9 |

3 |

|

M12×1.5 |

NB |

6H |

ITM6012ON |

82 |

10 |

40 |

42 |

8.5 |

6.5 |

9 |

4 |

|

M12×1.25 |

GB |

6H |

ITM6012NG |

82 |

15 |

40 |

42 |

8.5 |

6.5 |

9 |

3 |

|

M12×1.25 |

NB |

6H |

ITM6012NN |

82 |

10 |

40 |

42 |

8.5 |

6.5 |

9 |

4 |

|

M12×1 |

GB |

6H |

ITM6012MG |

82 |

12 |

40 |

42 |

8.5 |

6.5 |

9 |

3 |

|

M12×1 |

NB |

6H |

ITM6012MN |

82 |

6 |

40 |

42 |

8.5 |

6.5 |

9 |

4 |

|

M14×2 |

GB |

6H |

ITM6014QG |

88 |

20 |

43 |

45 |

10.5 |

8 |

11 |

3 |

|

M14×2 |

NB |

6H |

ITM6014QN |

88 |

12 |

43 |

45 |

10.5 |

8 |

11 |

4 |

|

M14×1.5 |

GB |

6H |

ITM6014OG |

88 |

20 |

43 |

45 |

10.5 |

8 |

11 |

3 |

|

M14×1.5 |

NB |

6H |

ITM6014ON |

88 |

12 |

43 |

45 |

10.5 |

8 |

11 |

4 |

|

M14×1.25 |

GB |

6H |

ITM6014NG |

88 |

15 |

43 |

45 |

10.5 |

8 |

11 |

3 |

|

M14×1.25 |

NB |

6H |

ITM6014NN |

88 |

12 |

43 |

45 |

10.5 |

8 |

11 |

4 |

|

M14×1 |

GB |

6H |

ITM6014MG |

88 |

12 |

43 |

45 |

10.5 |

8 |

11 |

3 |

|

M14×1 |

NB |

6H |

ITM6014MN |

88 |

6 |

43 |

45 |

10.5 |

8 |

11 |

4 |

|

M15×1.5 |

GB |

6H |

ITM6015OG |

95 |

19 |

47 |

48 |

12.5 |

10 |

13 |

3 |

|

M15×1.5 |

NB |

6H |

ITM6015ON |

95 |

10 |

47 |

48 |

12.5 |

10 |

13 |

4 |

|

M15×1 |

GB |

6H |

ITM6015MG |

95 |

12 |

47 |

48 |

12.5 |

10 |

13 |

3 |

|

M15×1 |

NB |

6H |

ITM6015MN |

95 |

10 |

47 |

48 |

12.5 |

10 |

13 |

4 |

|

M16×2 |

GB |

6H |

ITM6016QG |

95 |

20 |

47 |

48 |

12.5 |

10 |

13 |

3 |

|

M16×2 |

NB |

6H |

ITM6016QN |

95 |

12 |

47 |

48 |

12.5 |

10 |

13 |

4 |

|

M16×1.5 |

GB |

6H |

ITM6016OG |

95 |

20 |

47 |

48 |

12.5 |

10 |

13 |

3 |

|

M16×1.5 |

NB |

6H |

ITM6016ON |

95 |

12 |

47 |

48 |

12.5 |

10 |

13 |

4 |

|

M16×1 |

GB |

6H |

ITM6016MG |

95 |

12 |

47 |

48 |

12.5 |

10 |

13 |

3 |

|

M16×1 |

NB |

6H |

ITM6016MN |

95 |

8 |

47 |

48 |

12.5 |

10 |

13 |

4 |

|

M17×1.5 |

GB |

6H |

ITM6017OG |

100 |

19 |

49 |

51 |

14 |

11 |

14 |

3 |

|

M17×1.5 |

NB |

6H |

ITM6017ON |

100 |

10 |

49 |

51 |

14 |

11 |

14 |

4 |

|

M17×1 |

GB |

6H |

ITM6017MG |

100 |

12 |

49 |

51 |

14 |

11 |

14 |

3 |

|

M17×1 |

NB |

6H |

ITM6017MN |

100 |

10 |

49 |

51 |

14 |

11 |

14 |

4 |

|

M18×2.5 |

GB |

6H |

ITM6018RG |

100 |

25 |

49 |

51 |

14 |

11 |

14 |

3 |

|

M18×2.5 |

NB |

6H |

ITM6018RN |

100 |

16 |

49 |

51 |

14 |

11 |

14 |

4 |

|

M18×2 |

GB |

6H |

ITM6018QG |

100 |

20 |

49 |

51 |

14 |

11 |

14 |

3 |

|

M18×2 |

NB |

6H |

ITM6018QN |

100 |

12 |

49 |

51 |

14 |

11 |

14 |

4 |

|

M18×1.5 |

GB |

6H |

ITM6018OG |

100 |

20 |

49 |

51 |

14 |

11 |

14 |

3 |

|

M18×1.5 |

NB |

6H |

ITM6018ON |

100 |

12 |

49 |

51 |

14 |

11 |

14 |

4 |

|

M18×1 |

GB |

6H |

ITM6018MG |

100 |

12 |

49 |

51 |

14 |

11 |

14 |

3 |

|

M18×1 |

NB |

6H |

ITM6018MN |

100 |

8 |

49 |

51 |

14 |

11 |

14 |

4 |

|

M20×2.5 |

GB |

6H |

ITM6020RG |

105 |

25 |

55 |

50 |

15 |

12 |

15 |

5 |

|

M20×2.5 |

NB |

6H |

ITM6020RN |

105 |

16 |

55 |

50 |

15 |

12 |

15 |

6 |

|

M20×2 |

GB |

6H |

ITM6020QG |

105 |

20 |

55 |

50 |

15 |

12 |

15 |

5 |

|

M20×2 |

NB |

6H |

ITM6020QN |

105 |

12 |

55 |

50 |

15 |

12 |

15 |

6 |

|

M20×1.5 |

GB |

6H |

ITM6020OG |

105 |

20 |

55 |

50 |

15 |

12 |

15 |

5 |

|

M20×1.5 |

NB |

6H |

ITM6020ON |

105 |

12 |

55 |

50 |

15 |

12 |

15 |

6 |

|

M20×1 |

GB |

6H |

ITM6020MG |

105 |

14 |

55 |

50 |

15 |

12 |

15 |

5 |

|

M20×1 |

NB |

6H |

ITM6020MN |

105 |

8 |

55 |

50 |

15 |

12 |

15 |

6 |

|

M22×2.5 |

GB |

6H |

ITM6022RG |

115 |

33 |

60 |

55 |

17 |

13 |

16 |

5 |

|

M22×2.5 |

NB |

6H |

ITM6022RN |

115 |

16 |

60 |

55 |

17 |

13 |

16 |

6 |

|

M22×2 |

GB |

6H |

ITM6022QG |

115 |

20 |

60 |

55 |

17 |

13 |

16 |

5 |

|

M22×2 |

NB |

6H |

ITM6022QN |

115 |

14 |

60 |

55 |

17 |

13 |

16 |

6 |

|

M22×1.5 |

GB |

6H |

ITM6022OG |

115 |

20 |

60 |

55 |

17 |

13 |

16 |

5 |

|

M22×1.5 |

NB |

6H |

ITM6022ON |

115 |

14 |

60 |

55 |

17 |

13 |

16 |

6 |

|

M22×1 |

GB |

6H |

ITM6022MG |

115 |

14 |

60 |

55 |

17 |

13 |

16 |

5 |

|

M22×1 |

NB |

6H |

ITM6022MN |

115 |

8 |

60 |

55 |

17 |

13 |

16 |

6 |

|

M24×3 |

GB |

6H |

ITM6024SG |

120 |

30 |

65 |

55 |

19 |

15 |

18 |

5 |

|

M24×3 |

NB |

6H |

ITM6024SN |

120 |

20 |

65 |

55 |

19 |

15 |

18 |

6 |

|

M24×2 |

GB |

6H |

ITM6024QG |

120 |

20 |

65 |

55 |

19 |

15 |

18 |

5 |

|

M24×2 |

NB |

6H |

ITM6024QN |

120 |

14 |

65 |

55 |

19 |

15 |

18 |

6 |

|

M24×1.5 |

GB |

6H |

ITM6024OG |

120 |

20 |

65 |

55 |

19 |

15 |

18 |

5 |

|

M24×1.5 |

NB |

6H |

ITM6024ON |

120 |

14 |

65 |

55 |

19 |

15 |

18 |

6 |

|

M24×1 |

GB |

6H |

ITM6024MG |

120 |

14 |

65 |

55 |

19 |

15 |

18 |

5 |

|

M24×1 |

NB |

6H |

ITM6024MN |

120 |

8 |

65 |

55 |

19 |

15 |

18 |

6 |

| แบรนด์สินค้า | YAMAWA |

|---|