Compact Surface Roughness Instrument

SURFTEST SJ-410

Compact surface roughness instruments with a large high-visibility color LCD that helps with micro-form evaluation.

Measuring range (X axis): 25 mm, 50 mm

Measuring range (Z1 axis): 800 μm /80 μm/8 μm

SPECIFICATIONS

| Model | SJ-411 | SJ-412 | |||

| Order No. | inch /mm | 178-581-11A | 178-581-12A | 178-583-11A | 178-583-12A |

| Measuring range | X axis | 25mm (1") | 50mm (2") | ||

| Z axis (detector) | 800μm, 80μm, 8μm (32000μin, 3200μin, 320μin) Up to 2,400μm (96,000μin) when using an optional stylus. | ||||

| Detector | Detection method | Differential inductance | |||

| Resolution (Range) | 0.01μm (800μm) / 0.001μm (80μm) / 0.0001μm (8μm) 0.4μin (32000μin) / 0.04μin (3200μin) / 0.004μin (320μin) |

||||

| Stylus tip shape (Angle / Radius) | 60°/ 2μm (80μin) | 90°/ 5μm (200μin) | 60°/ 2μm (80μin) | 90°/ 5μm (200μin) | |

| Measuring force | 0.75 mN | 4 mN | 0.75 mN | 4 mN | |

| Radius of skid curvature | 40mm (1.57") | ||||

| Measuring methods | Skidless / Skidded (switchable) | ||||

| Drive unit (X axis) | Measuring speed | 0.05, 0.1, 0.2, 0.5, 1.0mm/s (0.002, 0.004, 0.02, 0.04 inch/s) | |||

| Drive speed | 0.5, 1, 2, 5mm/s (0.02, 0.04, 0.08, 0.2 inch/s) | ||||

| Straightness | 0.3μm / 25mm (12μin / 1") | 0.5μm / 50mm (20μin / 2") | |||

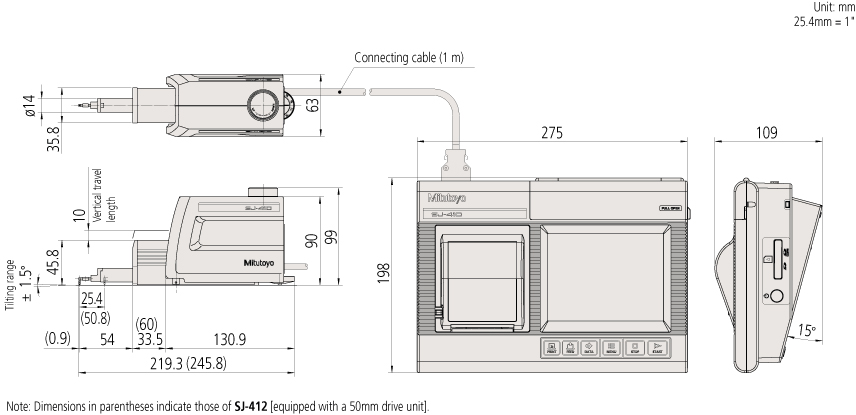

| Up/down inclination unit |

Vertical travel | 10mm (0.39") | |||

| Inclination adjustment angle | ±1.5° | ||||

| Applicable standards | JIS 1982 / JIS 1994 / JIS 2001 / ISO 1997 /ANSI/VDA | ||||

| Parameter | Ra, Rq, Rz, Ry, Rp, Rv, Rt, R3z, Rsk, Rku, Rc, RPc, RSm, Rmax*¹, Rz1max*², S, HSC, RzJIS*³, Rppi, RΔa, RΔq, Rlr, Rmr, Rmr (c), Rσc, Rk, Rpk, Rvk, Mr1, Mr2, A1, A2, Vo, λa,λq, Lo, Rpm, tp*⁴, Htp*4, R, Rx, AR, W, AW, Wx, Wte Customizable | ||||

| Filtered profile | Primary profile, Roughness profile, DF profile, Waviness profile, Roughness motif profile, Waviness motif profile | ||||

| Analysis graph | Material ratio curve, Profile height amplitude distribution curve | ||||

| Data compensation functions | Parabola, Hyperbola, Ellipse, Circle, Tilt, No compensation | ||||

| Filter | 2CR, PC75, Gaussian | ||||

| Cutoff value | λc | 0.08, 0.25, 0.8, 2.5, 8 mm (.003, .01, .03, .1, .3") | |||

| λs*⁵ | 2.5, 8, 25μm (100, 320, 1000μin) | ||||

| Sampling length | 0.08, 0.25, 0.8, 2.5, 8, 25 mm (.003, .01, .03, .1, .3, 1") | ||||

| Number of intervals | ×1, ×2, ×3, ×4, ×5, ×6, ×7, ×8, ×9, ×10, ×11, ×12, ×13, ×14, ×15, ×16, ×17, ×18, ×19, ×20 | ||||

| Arbitrary length | 0.1 to 25 mm (.0039 to 1") | 0.1 to 50 mm (.0039 to 2") | |||

| Calculation display unit |

Customization | Selection of display / evaluation roughness parameter | |||

| Simplified contour analysis function | Step, Step quantity, Area, Coordinate difference | ||||

| DAT (Digimatic Adjustment Table) function | Helps to level workpiece prior to skidless measurement | ||||

| Real sampling function | Inputs the displacement of the detector while stopping the drive unit | ||||

| statistical processing | Calculates the maximum value, minimum value, average value, standard deviation, pass rate and histogram for each parameter. | ||||

| Judgment*⁶ | Maximum value rule, 16 % rule, mean value rule, standard deviation (1σ, 2σ, 3σ) | ||||

| Storing measurement condition | Max. 10 (calculation display unit) | ||||

| Print function (Built-in thermal printer) |

Measurement condition / Calculation result / Judgment result / Calculation result per segment / Tolerance value / Evaluation curve / Graphic curve / Material ratio curve / Profile height amplitude distribution curve / Environmental setting items / Statistical result (Histogram) | ||||

| Display language | 16 languages (Japanese, English, German, French, Italian, Spanish, Portuguese, Korean, Chinese (simplified / traditional), Czech, Polish, Hungarian,Turkish, Swedish, Dutch) |

||||

| Storage function | Built-in memory: Measurement condition (Up to 10) Memory card (optional): 500 measurement conditions, 10000 measured profiles, 500 display images, 10000 text files, 500 statistical data, 1 backup file of device setting data, 10 data of Trace 10 |

||||

| External I / O functions | USB I / F, Digimatic output, RS-232C I / F, Foot switch I / F | ||||

| Power supply | Battery Charging time / Endurance |

Built-in battery (rechargeable Ni-MH battery) /AC adapter Charging time of the built-in battery: about 4 hours (may vary due to ambient temperature) Endurance: about 1000 measurements (differs slightly due to use conditions /environment) |

|||

| Max. power consumption | 50 W | ||||

| External dimensions (W×D×H) |

Calculation display unit | 275x198x109 mm (10.83x7.80x4.29") | |||

| Up /down inclination unit | 131x63x99 mm (5.16x2.48x3.9") | ||||

| Drive unit | 128x35.8x46.6 mm (5.04x1.41x1.83") | 154.Sx3S.8x46.6 mm (6.08x1.41x1.83") | |||

| Mass | Calculation display unit | 1.7 kg | |||

| Up /down inclination unit | 0.4 kg | ||||

| Drive unit | 0.6 kg | 0.64 kg | |||

| Standard Accessories |

Detector*⁷ / Standard stylus*⁸ AC adapter, Power cable, Flat-blade screwdriver, Phillips screwdriver, Hex wrench, Strap for the touch pen, Operation manual, One-sheet manual, Warranty card |

||||

*1 Calculation is available only when selecting the VDA, ANSI, or JIS 1982 standards.

*2 Calculation is available only when selecting the ISO 1997 standard.

*3 Calculation is available only when selecting the JIS 2001 standard.

*4 Calculation is available only when selecting the ANSI standard.

*5 Not available when selecting the JIS 1982 standard.

*6 Only the mean value rule is available for the ANSI standard. 16 % rule is not available when selecting the VDA standard.

*7 Depending on the Order No. of the SJ-410 Series main unit, 178-396 or 178-397 is provided as standard.

*8 Standard stylus (12AAC731 or 12AAB403) supporting the provided detector is provided as standard.

Note 1: Refer to pages 12 to 13 for details of Detector, Stylus and Nosepiece.

Note 2: To denote your AC line voltage add the following suffixes (e.g. 178-580-11A). A for 120 V, C for 100 V, D for 230 V, E for 230 V (for UK), DC for 220 V (for China), K for 220 V (for Korea)

| แบรนด์สินค้า | MITUTOYO |

|---|