Product Features

- The UH-CT is designed for tapping SKD and pre-hardened steel

50HRC to 63HRC (Max 63). - It is produced from a ultra fine grain cemented carbide with superior abrasion

resistance and impact resistance. - The UH-CT has an improved shank roundness accuracy.

- Recommended tapping length is "Major diameter size x 1.5" or less 5P chamfer for better tool life.

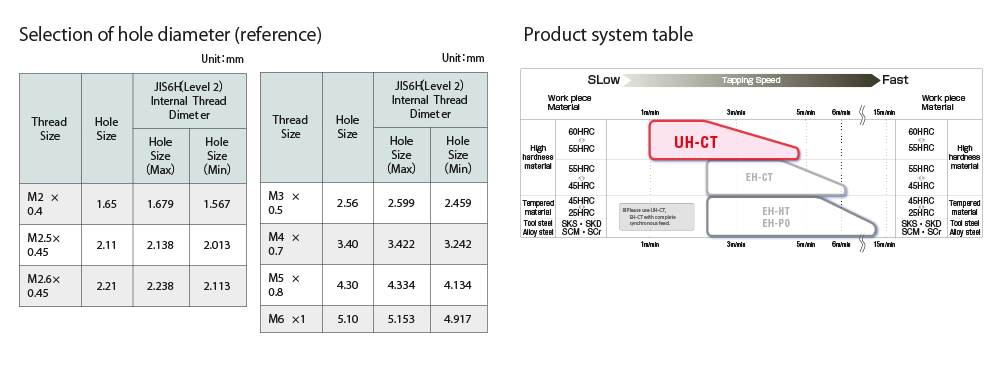

- For the bored hole diameter, the maximum minor diameter of a 6H internal thread diameter maximum value is recommended.

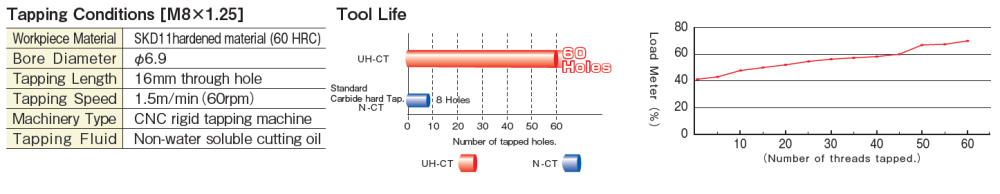

Tapping Data

The figure above is a comparison of the number of tapped holes using a standard carbide tap (N-CT) and a

carbide tap in SKD 11 high hardness quenched steel at 60 HRC. The N-CT tap, had chipped flutes at

8 holes. Compared to the N-CT, the UH-CT was able to process 60 holes in ultra high hardness steel. It is

important to watch for a dull drill as it will cause the taps flutes to wear prematurely. The drilling is

processed at a 6m/min. cutting speed and a 0.04mm/rev. feed which can easily cause work hardening.

・ Bored hole in this test was prepared by using a carbide drill under such condition as could cause no

work-hardening. (cutting speed: 6m/min, feed 0.04m/rev.)

The figure above shows the relationship between the

number of tapped holes and the load meter (%) of

the machine when machining tests are conducted up

to 60 holes with UH - CT tap. The numerical value

of the load meter tends to increase as the number of

tapped holes increase at 50 completed threads. The

cutting edge damage at this point causes the load

meter to raise quickly beyond 50 tapped holes. As

the number of tapped holes progresses further, the

risk of tap breakage is considerable and the load will

increase, so it is recommended to set the life

expectancy at a safe level considering the high

hardness of the steel being processed.

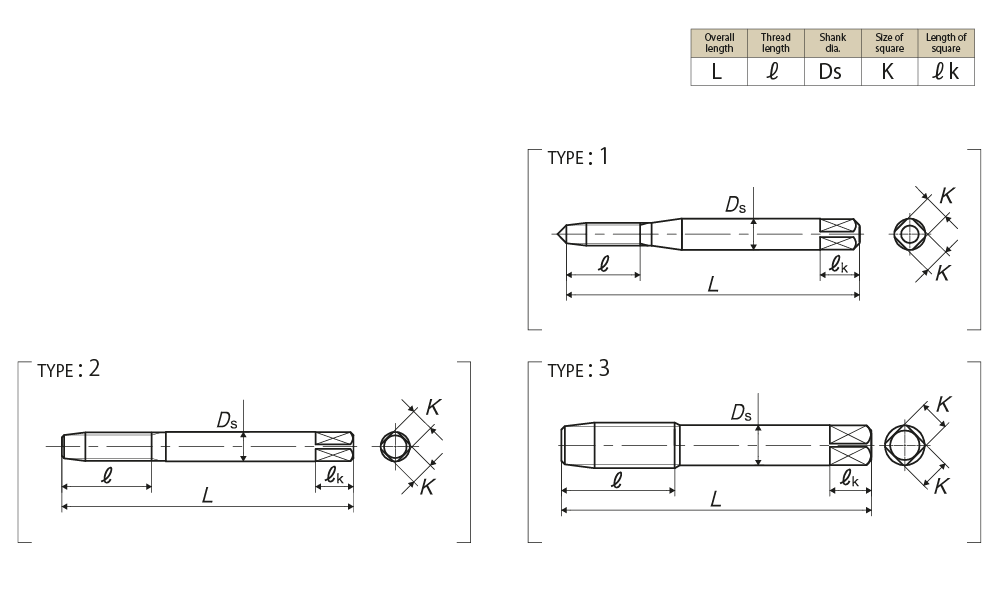

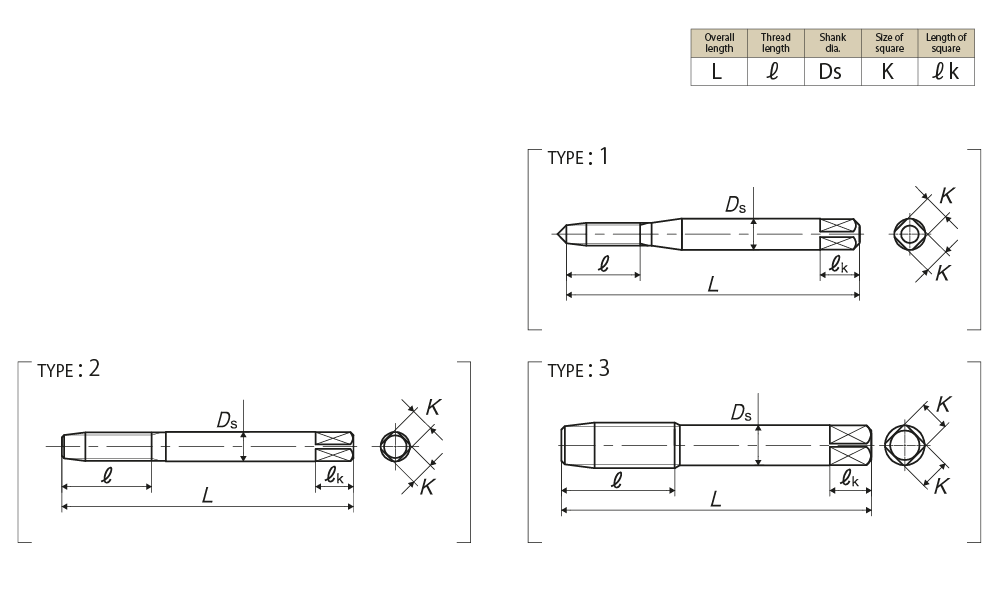

Specification

Tapping Speeds depending on Materials

Segment:1L

|

Size |

Class |

Code |

Chamfer |

L (mm) |

ℓ (mm) |

Ds (mm) |

K (mm) |

ℓk (mm) |

No. of flutes |

TYPE |

|

For Metric Threads |

||||||||||

|

M2×0.4 |

P3 |

UHCR2.0E5 |

5P |

40 |

8 |

4 |

3.2 |

6 |

3 |

1 |

|

M2.5×0.45 |

P3 |

UHCR2.5F5 |

5P |

44 |

9.5 |

4 |

3.2 |

6 |

4 |

1 |

|

M2.6×0.45 |

P3 |

UHCR2.6F5 |

5P |

44 |

9.5 |

4 |

3.2 |

6 |

4 |

1 |

|

M3×0.5 |

P3 |

UHCR3.0G5 |

5P |

46 |

11 |

5 |

4 |

7 |

4 |

1 |

|

M4×0.7 |

P3 |

UHCR4.0I5 |

5P |

52 |

13 |

5.5 |

4.5 |

7 |

4 |

1 |

|

M5×0.8 |

P3 |

UHCR5.0K5 |

5P |

60 |

16 |

6 |

4.5 |

7 |

4 |

1 |

|

M6×1 |

P3 |

UHCR6.0M5 |

5P |

62 |

19 |

6.2 |

5 |

8 |

5 |

2 |

|

M8×1.25 |

P4 |

UHCS8.0N5 |

5P |

70 |

22 |

7 |

5.5 |

8 |

5 |

3 |

|

M10×1.5 |

P4 |

UHCS010O5 |

5P |

75 |

24 |

8.5 |

6.5 |

9 |

5 |

3 |

|

M10×1.25 |

P4 |

UHCS010N5 |

5P |

75 |

24 |

8.5 |

6.5 |

9 |

5 |

3 |

|

M12×1.75 |

P4 |

UHCS012P5 |

5P |

82 |

30 |

10.5 |

8 |

11 |

5 |

3 |

|

M12×1.5 |

P4 |

UHCS012O5 |

5P |

82 |

30 |

10.5 |

8 |

11 |

5 |

3 |

|

M12×1.25 |

P4 |

UHCS012N5 |

5P |

82 |

30 |

10.5 |

8 |

11 |

5 |

3 |

|

M14×2 |

P4 |

UHCS014Q5 |

5P |

88 |

30 |

12.5 |

10 |

13 |

6 |

3 |

|

M14×1.5 |

P4 |

UHCS014O5 |

5P |

88 |

30 |

12.5 |

10 |

13 |

6 |

3 |

|

M16×2 |

P4 |

UHCS016Q5 |

5P |

95 |

30 |

14 |

11 |

14 |

6 |

3 |

|

M16×1.5 |

P4 |

UHCS016O5 |

5P |

95 |

30 |

14 |

11 |

14 |

6 |

3 |

|

M18×2.5 |

P4 |

UHCS018R5 |

5P |

100 |

35 |

15 |

12 |

15 |

6 |

3 |

|

M18×1.5 |

P4 |

UHCS018O5 |

5P |

100 |

35 |

15 |

12 |

15 |

6 |

3 |

|

M20×2.5 |

P4 |

UHCS020R5 |

5P |

105 |

35 |

17 |

13 |

16 |

6 |

3 |

|

M20×1.5 |

P4 |

UHCS020O5 |

5P |

105 |

35 |

17 |

13 |

16 |

6 |

3 |

Note: Ds, K and ℓk of UH-CT are one rank higher than those of standard tap dimensions.

| แบรนด์สินค้า | YAMAWA |

|---|