YS2-CS

|

商品コード Item code |

在庫 Stock |

寸法 Size (mm) | |||

|

外径 Tool dia. |

刃長 Flute length |

全長 Overall length |

シャンク径 Shank dia. |

||

| YS2002-CS | 0.2 | □ | 0.4 | 40 | 4 |

| YS2003-CS | 0.3 | □ | 0.6 | 40 | 4 |

| YS2004-CS | 0.4 | □ | 0.8 | 40 | 4 |

| YS2005-CS | 0.5 | □ | 1 | 40 | 4 |

| YS2006-CS | 0.6 | □ | 1.2 | 40 | 4 |

| YS2007-CS | 0.7 | □ | 1.4 | 40 | 4 |

| YS2008-CS | 0.8 | □ | 1.6 | 40 | 4 |

| YS2009-CS | 0.9 | □ | 1.8 | 40 | 4 |

| YS2010-CS | 1 | □ | 2 | 40 | 4 |

| YS2015-CS | 1.5 | □ | 3 | 40 | 4 |

| YS2020-CS | 2 | □ | 6 | 40 | 4 |

| YS2025-CS | 2.5 | □ | 8 | 40 | 4 |

| YS2030-CS | 3 | □ | 8 | 45 | 6 |

| YS2035-CS | 3.5 | □ | 10 | 45 | 6 |

| YS2040-CS | 4 | □ | 11 | 45 | 6 |

| YS2045-CS | 4.5 | □ | 11 | 45 | 6 |

| YS2050-CS | 5 | □ | 13 | 50 | 6 |

| YS2055-CS | 5.5 | □ | 13 | 50 | 6 |

| YS2060-CS | 6 | □ | 13 | 50 | 6 |

| YS2070-CS | 7 | □ | 16 | 60 | 8 |

| YS2080-CS | 8 | □ | 19 | 60 | 8 |

| YS2090-CS | 9 | □ | 19 | 70 | 10 |

| YS2100-CS | 10 | □ | 22 | 70 | 10 |

| YS2120-CS | 12 | □ | 26 | 75 | 12 |

| YS2160-CS | 16 | □ | 35 | 90 | 16 |

| YS2200-CS | 20 | □ | 40 | 105 | 20 |

◎ YS-CS、YR-CS の対応被削材

Applicable work material of YS-CS, YR-CS

|

炭素鋼合金鋼 Carbon steel Alloy steel |

プリハードン鋼 Pre-hardened steel≦ 45HRC |

高硬度 Hardened steel |

ステンレス鋼 Stainless steel |

チタン合金耐熱合金 Titanium alloy Heat-resistant alloy |

銅合金 Copper alloy |

アルミ合金 Aluminum alloy |

||

|

> 45HRC ≦ 55HRC |

> 55HRC ≦ 65HRC |

> 65HRC | ||||||

| ◎ | ○ | ○ | ○ | ◎ | ◎ | |||

□ 印:特定代理店在庫です。弊社営業へお問合せください。 □:Stocked by specified distributor. Contact with our sales department.

| แบรนด์สินค้า | MOLDINO |

|---|

ピンカド®・ショート刃長 Pinkado, Short

![]()

![]()

YS-CS

2枚刃・ショート刃長・ピンカド

2ft, Short, Pinkado

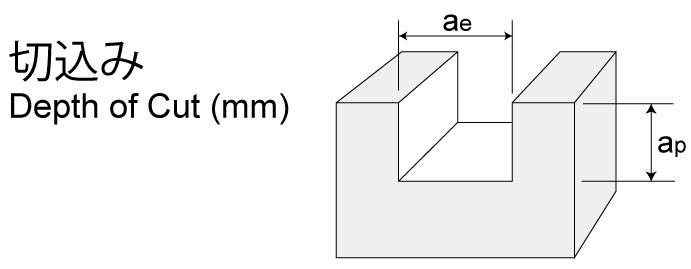

| DC<φ1 | |

| DC<φ1 | 0.1DC |

| φ1≦DC<φ3 | 0.3DC |

| φ3≦DC | 0.5DC |

<溝切削>Slotting

|

被削材 Work material |

銅合金・アルミ合金 Copper alloys, Aluminum alloys |

鋳鉄・炭素鋼 Cast irons, Carbon steels |

ステンレス鋼 Stainless steels SUS304、SUS316 |

合金鋼・工具鋼 Alloy steels, Tool steels |

プリハードン鋼・焼入れ鋼 Pre-hardened steels, Hardened steels CENA1、NAK80、SKD |

|||||

| 硬度 Hardness | - | ~250HB | - | 25~35HRC | 35~45HRC | |||||

|

切削条件外径 Conditions DC mm |

vc=90~110m/min | vc=40~50m/min | vc=25~35m/min | vc=20~30m/min | vc=25~35m/min | |||||

|

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

|

| 0.2 | 30,000 ~50,000 |

300~500 | 20,000 ~50,000 |

100~500 | 10,000 ~30,000 |

70~300 | 10,000 ~30,000 |

70~300 | 10,000 ~30,000 |

50~200 |

| 0.5 | ||||||||||

| 0.8 | ||||||||||

| 1 | 32,000 | 300 | 14,000 | 100 | 9,000 | 67 | 9,500 | 70 | 8,000 | 50 |

| 1.5 | 20,000 | 300 | 9,500 | 120 | 5,700 | 76 | 6,000 | 80 | 5,000 | 50 |

| 2 | 16,000 | 300 | 7,100 | 120 | 4,600 | 76 | 4,800 | 80 | 4,000 | 50 |

| 3 | 11,000 | 300 | 4,700 | 140 | 2,900 | 86 | 3,100 | 90 | 2,600 | 55 |

| 4 | 8,000 | 300 | 3,500 | 140 | 2,200 | 86 | 2,300 | 90 | 1,900 | 55 |

| 5 | 6,400 | 300 | 2,800 | 140 | 1,800 | 86 | 1,900 | 90 | 1,600 | 55 |

| 6 | 5,300 | 300 | 2,300 | 140 | 1,400 | 86 | 1,500 | 90 | 1,300 | 55 |

| 8 | 4,000 | 300 | 1,700 | 140 | 1,000 | 86 | 1,100 | 90 | 990 | 60 |

| 10 | 3,200 | 300 | 1,400 | 140 | 900 | 90 | 950 | 95 | 790 | 60 |

| 12 | 2,700 | 300 | 1,100 | 140 | 750 | 90 | 790 | 95 | 660 | 60 |

| 16 | 2,000 | 300 | 800 | 140 | 500 | 90 | 550 | 95 | 450 | 60 |

| 20 | 1,600 | 300 | 650 | 140 | 400 | 90 | 450 | 95 | 350 | 60 |

【注意】

①被削材、加工形状に合わせて、適切なクーラントを使用してください。

②この標準切削条件表は切削条件の目安を示すものです。実際の加工では加工形状、目的、使用機械等により条件を調整してください。

③4枚刃は溝切削に適しません。

【Note】

①Use the appropriate coolant for the work material and machining shape.

②These Recommended Cutting Conditions indicate only the rule of a thumb for the cutting conditions. In actual machining,

the condition should be adjusted accordingto the machining shape, purpose and the machine type.

③4-Flutes type is not suited to slotting.

YS-CS YR-CS

2枚刃・ ショート刃長・ ピンカド 4枚刃・レギュラー刃長・ ピンカド

2ft, Short, Pinkado 4ft, Regular, Pinkado

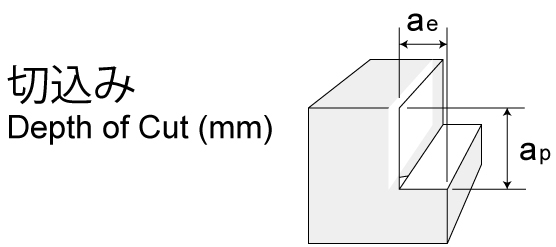

| ae | ap | |

| DC<φ3 | 0.05DC以下 | 1.5DC以下 |

| φ3≦DC | 0.1DC以下 |

<側面切削> Side Milling

|

被削材 Work material |

銅合金・アルミ合金 Copper alloys, Aluminum alloys |

鋳鉄・炭素鋼 Cast irons, Carbon steels FC200、SS400、S50C |

ステンレス鋼 Stainless steels SUS304、SUS316 |

合金鋼・工具鋼 Alloy steels, Tool steels SCM、SKD、ARK1 |

プリハードン鋼・焼入れ鋼 Pre-hardened steels, Hardened steels CENA1、NAK80、SKD |

|||||

| 硬度 Hardness | - | ~250HB | - | 25~35HRC | 35~45HRC | |||||

|

切削条件外径 Conditions DC mm |

vc=180~200m/min | vc=80~90m/min | vc=25~35m/min | vc=50~60m/min | vc=40~50m/min | |||||

|

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

回転数n Revolition min-1 |

送り速度vf Table Speed mm/min |

|

| 0.2 | 30,000 ~50,000 |

600~1,000 | 30,000 ~50,000 | 220~1,000 | 25,000 ~40,000 | 160~700 | 25,000 ~40,000 | 160~700 | 20,000 ~38,000 | 60~240 |

| 0.5 | ||||||||||

| 0.8 | ||||||||||

| 1 | 20,000 | 600 | 20,000 | 220 | 15,200 | 150 | 16,000 | 160 | 12,000 | 60 |

| 2 | 20,000 | 700 | 12,000 | 250 | 7,600 | 190 | 8,000 | 200 | 6,500 | 80 |

| 3 | 20,000 | 750 | 9,500 | 280 | 5,500 | 210 | 5,800 | 220 | 4,700 | 90 |

| 4 | 16,000 | 800 | 7,100 | 280 | 4,100 | 210 | 4,300 | 220 | 3,500 | 90 |

| 5 | 12,500 | 800 | 5,600 | 280 | 3,300 | 210 | 3,500 | 220 | 2,800 | 90 |

| 6 | 10,600 | 900 | 4,700 | 280 | 2,800 | 210 | 2,900 | 220 | 2,300 | 90 |

| 8 | 8,000 | 950 | 3,500 | 280 | 2,000 | 210 | 2,100 | 220 | 1,700 | 100 |

| 10 | 6,400 | 950 | 2,800 | 280 | 1,600 | 210 | 1,700 | 220 | 1,400 | 100 |

| 12 | 5,300 | 950 | 2,300 | 280 | 1,300 | 210 | 1,400 | 220 | 1,100 | 100 |

| 16 | 4,000 | 950 | 1,700 | 280 | 950 | 210 | 1,000 | 220 | 800 | 100 |

| 20 | 3,200 | 950 | 1,400 | 280 | 760 | 210 | 800 | 220 | 650 | 100 |

【注意】

① 被削材、加工形状に合わせて、適切なクーラントを使用してください。

② この標準切削条件表は切削条件の目安を示すものです。実際の加工では 加工形状、目的、使用機械等により条件を調整してください。

③ 上記の切削条件は2枚刃の場合を示します。4枚刃は送り速度を1.5倍にしてください

【Note】

①Use the appropriate coolant for the work material and machining shape.

②These Recommended Cutting Conditions indicate only the rule of a thumb for the cutting conditions. In actual machining, the condition should be adjusted according to the machining shape, purpose and the machine type.

③The cutting conditions given above is applied to 2-flute type end mills. As for 4-flute type, increase the feed by 1.5 times.