Product Features

- The tap is produced from high grade powder high speed steel material that has excellent heat resistance and abrasion resistance properties.

- Cutting edge geometry is designed to accommodate for thread shrinkage and the high temperature of difficult to machine materials.

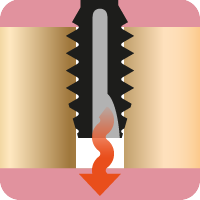

- Utilizes the appropriate flute shape and rake angles for nickel base alloy to allow a smooth discharge of chips.

- YAMAWA uses the ideal surface treatment to prevent chip welding and abrasion.

- Compensating for diameter shrinkage of the internal screw thread, the tap is produced moderately oversize.

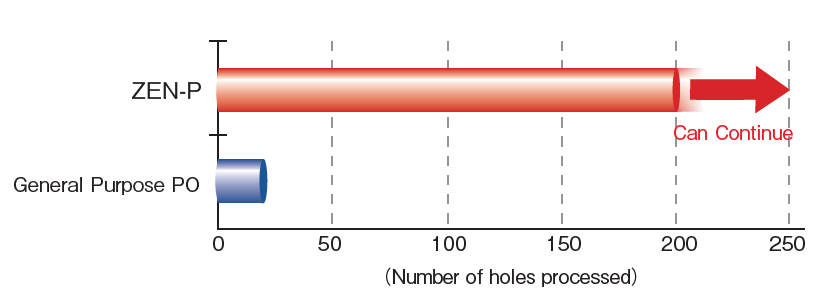

Tapping Data

Tapping Condition [M6×1]

| Workpiece Material | Hastelloy C-276 |

| Bored Hole Size | φ5.0 |

| Tapping Length | 10mm |

| Tapping Speed | 5m/min |

| Machinery Type | CNC tapping machine |

| Tapping Fluid | Water soluble cutting fluid |

Characteristics of nickel base alloys.

- Nickel based alloys have much better corrosion resistance and heat resistance than steel. In general, nickel based alloys are much more difficult to process than steels and stainless steels. Nickel based alloys include A286, inconels, hastelloys,Waspaloys and more. There are many kinds of nickel based alloys, but one of the more difficult ones to cut is inconel 718.

Types of problems tapping nickel based alloys.

- Nickel based alloys have a high temperature strength and thermal diffusion is small. Abrasion occurs quickly on the taps cutting edge.

- The internal thread diameters tend to spring back and may cause shrinkage and the tap may be crimped causing breakage.

- The material causes chip welding on the cutting chamfer and the flank surface of the tap's threads. The finished surface of

the internal screw thread produced from nickel based alloys can become rough and coarse.

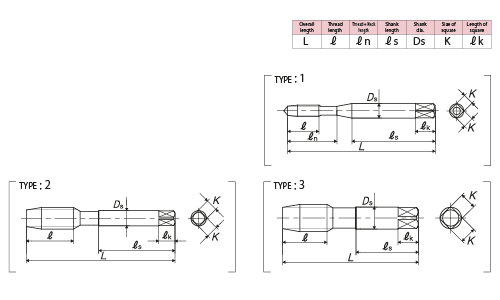

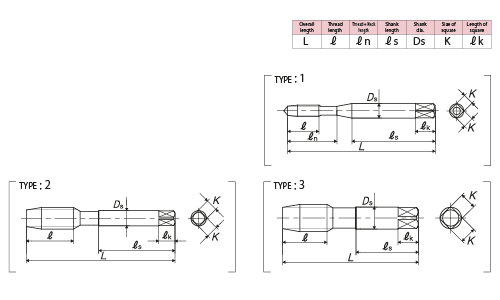

Specification

Tapping Speeds depending on Materials

Segment:1F

|

Size |

Class |

Code |

Chamfer |

L (mm) |

ℓ (mm) |

ℓn (mm) |

ℓs (mm) |

Ds (mm) |

K (mm) |

ℓk (mm) |

No. of flutes |

TYPE |

|

For Unified Threads |

||||||||||||

|

No.4-40UNC |

P3 |

ZENPMRUN4H |

4.5P |

46 |

9 |

14 |

25 |

4 |

3.2 |

6 |

2 |

1 |

|

No.6-32UNC |

P3 |

ZENPMRUN6J |

4.5P |

52 |

11 |

17 |

27 |

5 |

4 |

7 |

3 |

1 |

|

No.8-32UNC |

P3 |

ZENPMRUN8J |

4.5P |

60 |

13 |

22 |

31 |

5.5 |

4.5 |

7 |

3 |

1 |

|

No.10-24UNC |

P3 |

ZENPMRUNAM |

4.5P |

60 |

13 |

22 |

32 |

5.5 |

4.5 |

7 |

3 |

1 |

|

No.10-32UNF |

P3 |

ZENPMRUNAJ |

4.5P |

60 |

13 |

22 |

32 |

5.5 |

4.5 |

7 |

3 |

1 |

|

1/4-20UNC |

P3 |

ZENPMRU04N |

4.5P |

62 |

15 |

26 |

33 |

6 |

4.5 |

7 |

3 |

1 |

|

1/4-28UNF |

P3 |

ZENPMRU04K |

4.5P |

62 |

15 |

26 |

33 |

6 |

4.5 |

7 |

3 |

1 |

|

5/16-18UNC |

P4 |

ZENPMSU05O |

4.5P |

70 |

19 |

- |

36 |

6.2 |

5 |

8 |

3 |

2 |

|

5/16-24UNF |

P4 |

ZENPMSU05M |

4.5P |

70 |

19 |

- |

36 |

6.2 |

5 |

8 |

3 |

2 |

|

3/8-16UNC |

P4 |

ZENPMSU06P |

4.5P |

75 |

23 |

- |

38 |

7 |

5.5 |

8 |

3 |

2 |

|

3/8-24UNF |

P4 |

ZENPMSU06M |

4.5P |

75 |

23 |

- |

38 |

7 |

5.5 |

8 |

3 |

2 |

|

7/16-14UNC |

P4 |

ZENPMSU07Q |

4.5P |

82 |

26 |

- |

42 |

8.5 |

6.5 |

9 |

3 |

2 |

|

7/16-20UNF |

P4 |

ZENPMSU07N |

4.5P |

82 |

26 |

- |

42 |

8.5 |

6.5 |

9 |

3 |

2 |

|

1/2-13UNC |

P5 |

ZENPMTU08R |

4.5P |

88 |

26 |

- |

45 |

10.5 |

8 |

11 |

3 |

2 |

|

1/2-20UNF |

P4 |

ZENPMSU08N |

4.5P |

88 |

26 |

- |

45 |

10.5 |

8 |

11 |

3 |

2 |

|

5/8-11UNC |

P5 |

ZENPMTU10U |

4.5P |

95 |

26 |

- |

48 |

12.5 |

10 |

13 |

3 |

2 |

|

5/8-18UNF |

P4 |

ZENPMSU10O |

4.5P |

95 |

26 |

- |

48 |

12.5 |

10 |

13 |

3 |

2 |

|

3/4-10UNC |

P5 |

ZENPMTU12V |

4.5P |

105 |

33 |

- |

50 |

15 |

12 |

15 |

3 |

3 |

|

3/4-16UNF |

P5 |

ZENPMTU12P |

4.5P |

105 |

33 |

- |

50 |

15 |

12 |

15 |

3 |

3 |

| แบรนด์สินค้า | YAMAWA |

|---|---|

| Order No. | No.4-40UNC (ZENPMRUN4H) |

| Model | ZEN-P |

| Size | No.4-40UNC |

| Class | P3 |

| Chamfer | 4.5P |

| Overall length (L) | 46 |

| Thread length (ℓ) | 9 |

| Thread + Neck length (ℓn) | 14 |

| Shank length (ℓs) | 25 |

| Shank dia. (Ds) | 4 |

| Size of Square (K) | 3.2 |

| Length of square (ℓk) | 6 |