No.039 About tap regrinding

I would like to continue using my worn taps by resharpening them. Can you tell me the critical points I have to keep in mind when regrinding my used taps.

I would like to continue using my worn taps by resharpening them. Can you tell me the critical points I have to keep in mind when regrinding my used taps.

The cutting performance and stability of a tap is dependent on a balance of several elements such as the cutting angle, the chamfer relief and the margin width. It is difficult to resharpen a standard tap that was designed to run at high speeds. It is even more difficult to recreate the grind and produce the same cutting performance of a special tap that was developed for a specific industry. You need to be very careful when regrinding taps as any type of tap regrinding may cause problems with duplicating the original performance of the tap.

Guide

Surface areas available for regrinding used taps and issues of concern.

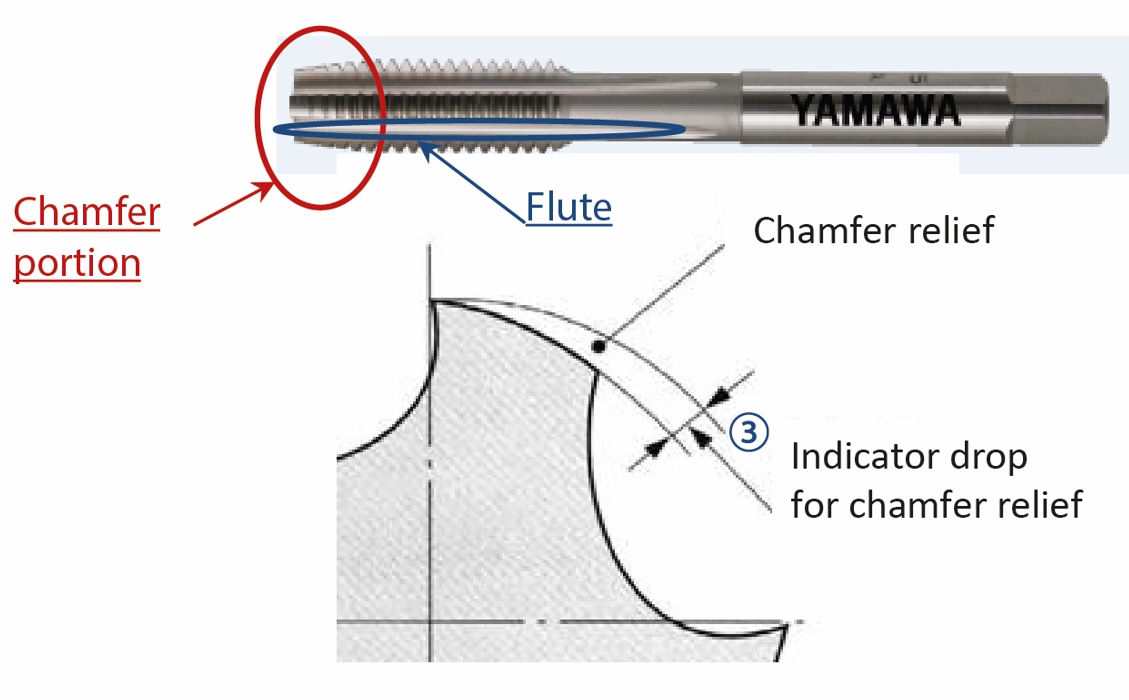

Example: Hand Taps. The surface areas available for regrinding a worn tap are the chamfer angle and the inside of each flute.

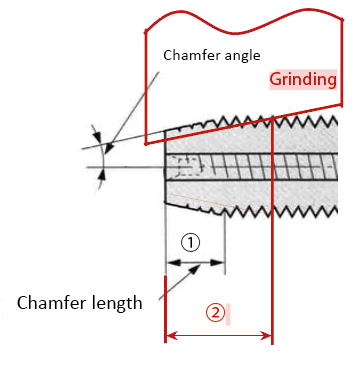

When taps are reground, it is essential to maintain the same chamfer angle to recreate an identical cutting performance to that of a new tap. Regrinding the chamfer extends its length from ① to length ② as shown above. The extra length of the chamfer is normally acceptable in tapping through holes but the front end of the resharpened tap will likely hit the bottom of the hole when tapping blind holes. Recreating the taps chamfer original length by cutting off the front end of the tap may be necessary but it will increase the grinding time and increase resharpening costs.

The chamfer relief is ground in a tangent curve to the outside diameter of the tap. The chamfer relief is not in a simple circular arc that is concentric to the diameter of the tap. The indicator drop for the chamfer relief ③ shown above changes depending on the tap type. It is difficult to select the indicator drop without proper instructions and reference charts to use as a guide.

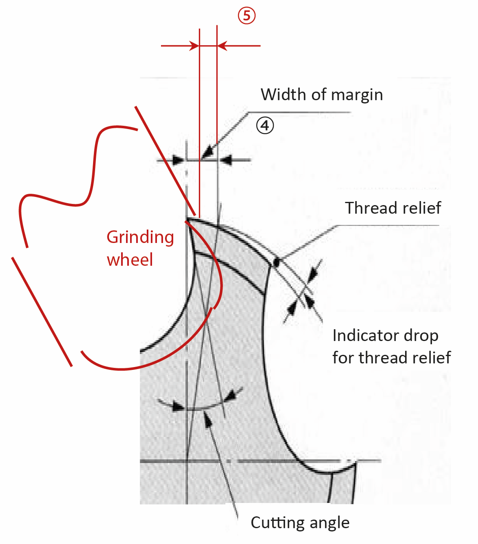

When regrinding inside the flutes, it is mandatory to maintain the same cutting angle of the orginal tap to recreate an identical cutting performance to that of a new tap. Regrinding inside the flutes will result in decreasing the width of the circular margin from ④ to ⑤ as shown at the right. This can cause an unstable tapping performance.