เครื่องมือกัดแต่งโลหะ

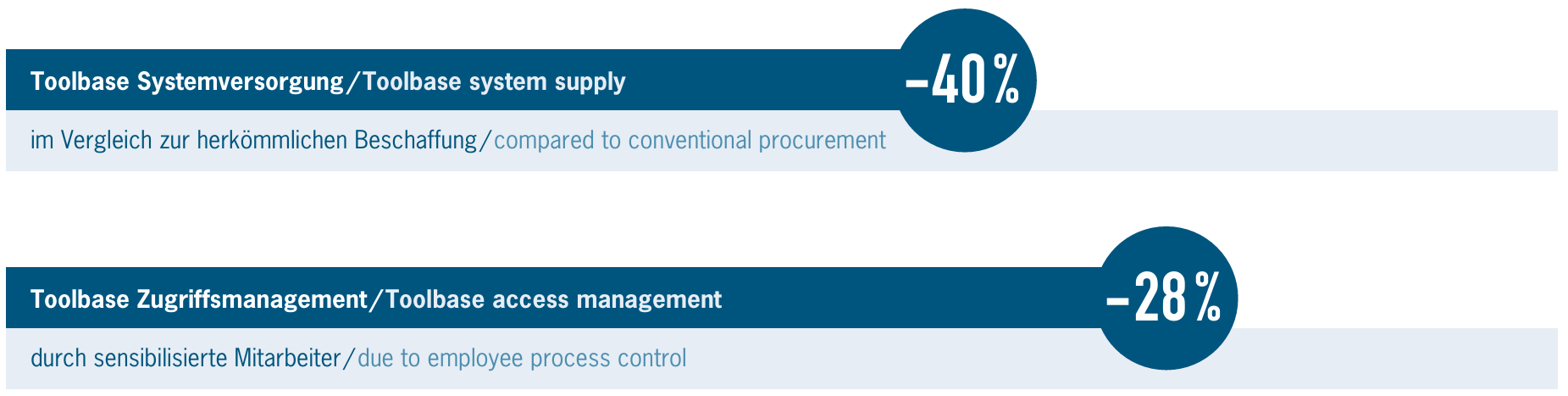

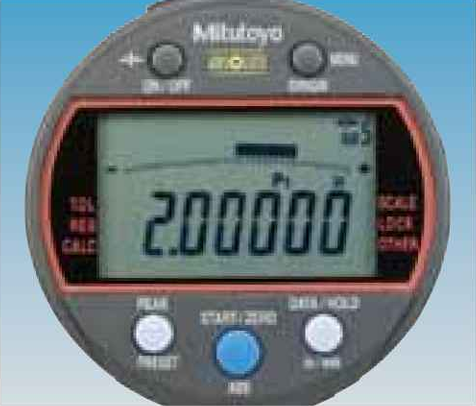

World’s highest water-proof/dust-proof rating (IP66) combined with a 35mm body width

|

1. Proven ABS (absolute) sensor Mitutoyo’s unique ABS (Absolute) sensor restores the last origin position automatically when the indicator is turned on. This allows quick-start operation, which is especially useful in multipoint measurement. Also, INC (Incremental) measurements can be made from any arbitrary position at the touch of a button, with restoration to ABS measurement mode being just as easy. |

|

2. Rated to IP66 water- and dust proofing standard and oil resistance improved This indicator can be used satisfactorily even in adverse environments where it is subject

|

|

|

3. Slim body design is advantageous for multi point measurements Slim design extends the application range to multipoint measurement and allows fixture downsizing. |

|

|

4. Improvement |

The Haimer Group is now a global competence partner and offers its worldwide customers WinTool and Toolbase products as a full-service provider.

|

SIMPLE PROCUREMENT With the Toolbase dispensing system customi zed to your needs, cost-intensive processes such as ongoing inventory control, demand determination and ordering via purchasing are a thing of the past.

|

EFFICIENT PROCESSES An automated system reduces your process costs in procurement, while the reliability of the supply for your tools and other consumables increases.

|

SYSTEM SUPPLY Now, everything is automated, with complete transparency at the same time. Current inven tory and consumption data are also available in the shop-floor systems. Process designs, simulations: Everything is simple. At the same time, cost control increases while process costs decrease. |

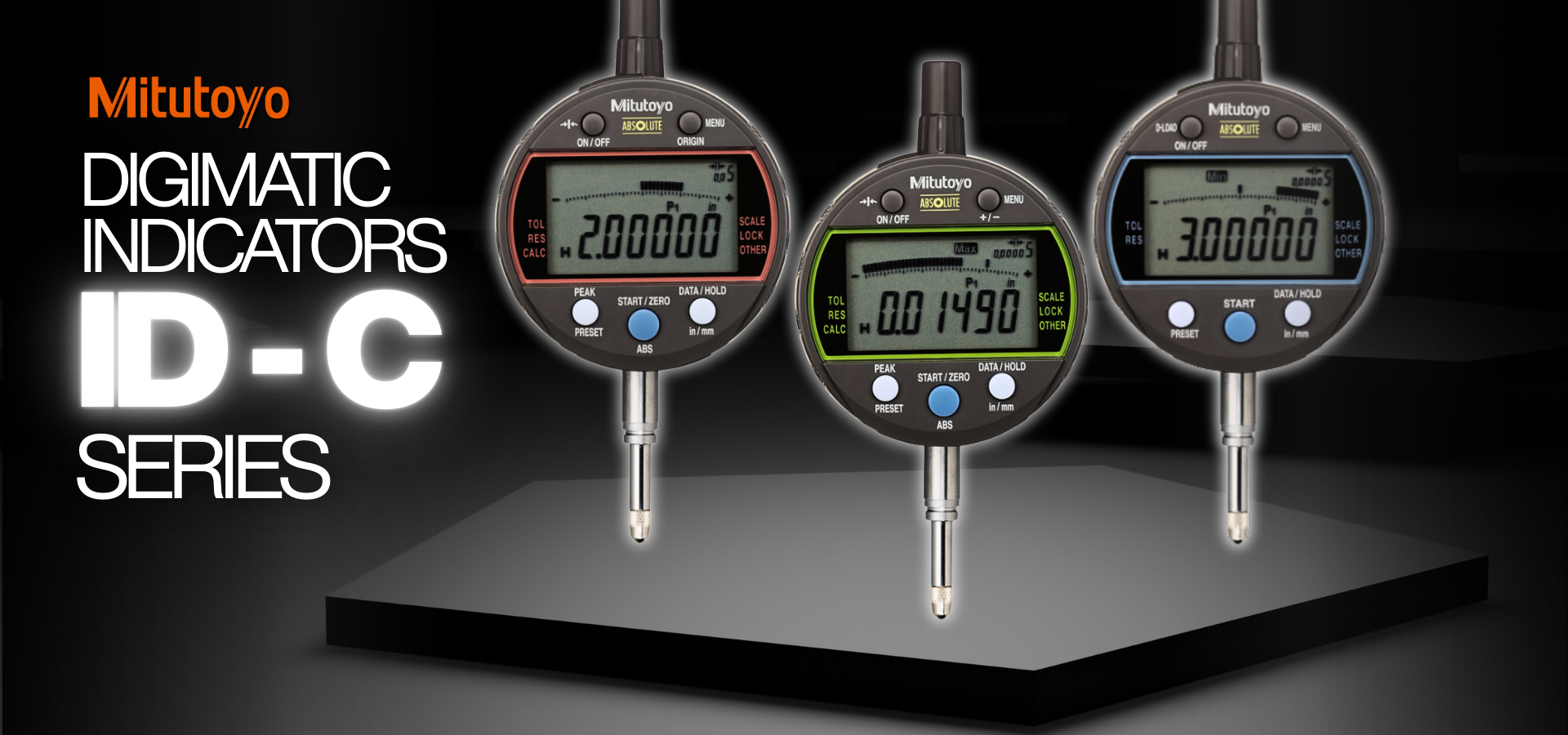

SAVE COSTS WITH TOOLBASE

|

AMORTISATION / AMORTIZATION: 6 - 18 MONATE / MONTHS |

Toolbase systems pay off very quickly. Efficiency potentials |

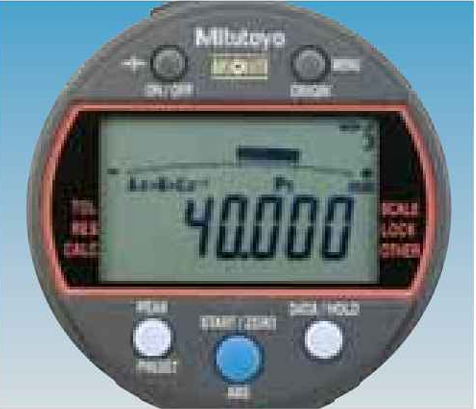

For Calculation, Peak-Value Hold and Bore Gage Applications

|

FEATURES Calculation function operates on spindle displacement. Entering the appropriate formula factors for a fixture dedicated to the application enables direct measurement readout, thereby eliminating any need for the conversion tables. previously needed for those applications where fixtures are typically used. Peak-Value TIR/MAX/MIN Hold enables GO/±NG judgement for peak value. Simple operation of many functions with five buttons and status icons. Wide LCD and new analog bar graph are now standard on all models. It performs sampling in fifty times per second and it enables to detect peak value more correctly. |

||

|

|

|

|

|

FEATURES Peak-Value TIR/MAX/MIN Hold enables GO/±NG judgement for peak value. Simple operation of many functions with five buttons and status icons Wide LCD and new analog | ||

Drill Chucks are three-jaw chucks to tighten the cutting tools, such as drill bit or reamer, by a chuck key. Yukiwa Drill Chucks are manufactured based on our standard which is higher than Japanese Industrial Standards (JIS) B4634 for Drill Chucks for machine tools. Therefore, it is possible to do the high precision works on the high precision professional drilling machines or lathes. We, Yukiwa Seiko, have started producing the Drill Chucks at Japan in 1951.

We have continued the technology studies for a long time, and the high accuracy, high quality and high durability are recognized world wide. We are now one of the big three biggest manufacturers of Drill Chucks in the world. Recently, in the market, there are a lot of Drill Chucks made in all over the world. If the high precision works are required for a long time, please use Yukiwa Drill Chucks. You can realize the differences.

Yukiwa Seiko is only Drill Chucks manufacturer

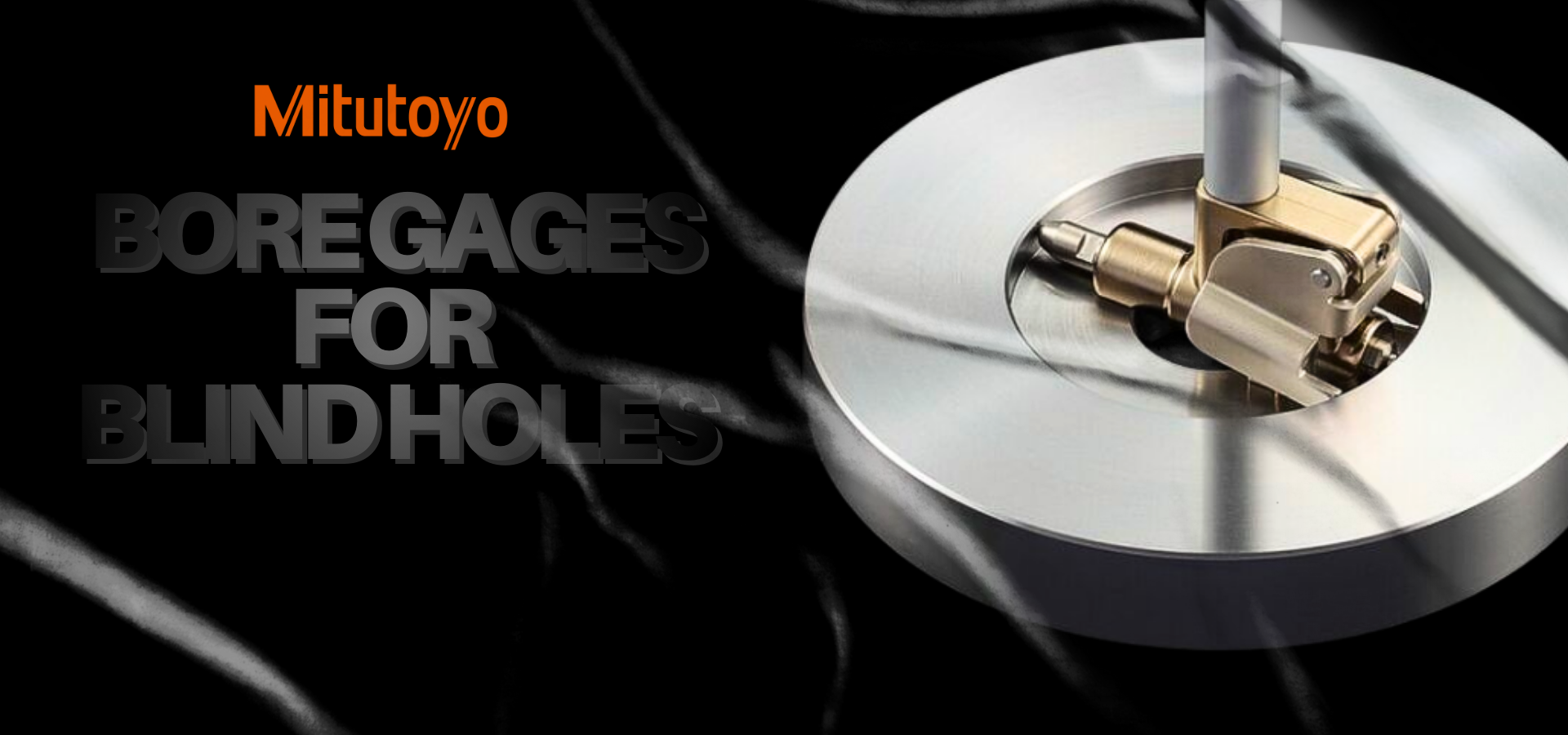

New model measures blind-hole diameter with high accuracy and high durability

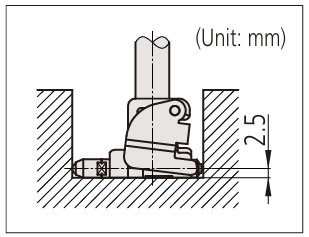

Capable of ID (inside diameter) measurementclose to the bottom of a hole.

Pendulum guide structure improves sliding.

Carbide contact faces for durability.

Grip is large and hollow to reduce effect of body heat on high-accuracy measurements.

Extension rods (optional) can be attached for measuring deep holes.

A Bore Gage Checker and a range of Setting Rings are available to aid in accurately setting a gage before making a measurement.

Alternative indicators may be used in place of those recommended*.

*Some indicators and protection covers cannot be usedwith these bore gages. Contact a Mitutoyo sales office ifconsidering the use of Dial or Digimatic indicators otherthan the recommended models.

| Order No. | 511-415 | 511-425 | 511-435 | 511-416 | 511-426 | 511-436 | 511-417 | 511-427 | 511-437 | |

| Measuring range | 15-35mm | 35-60mm | 35-60mm | |||||||

| lndicators (low/high resolution) | ||||||||||

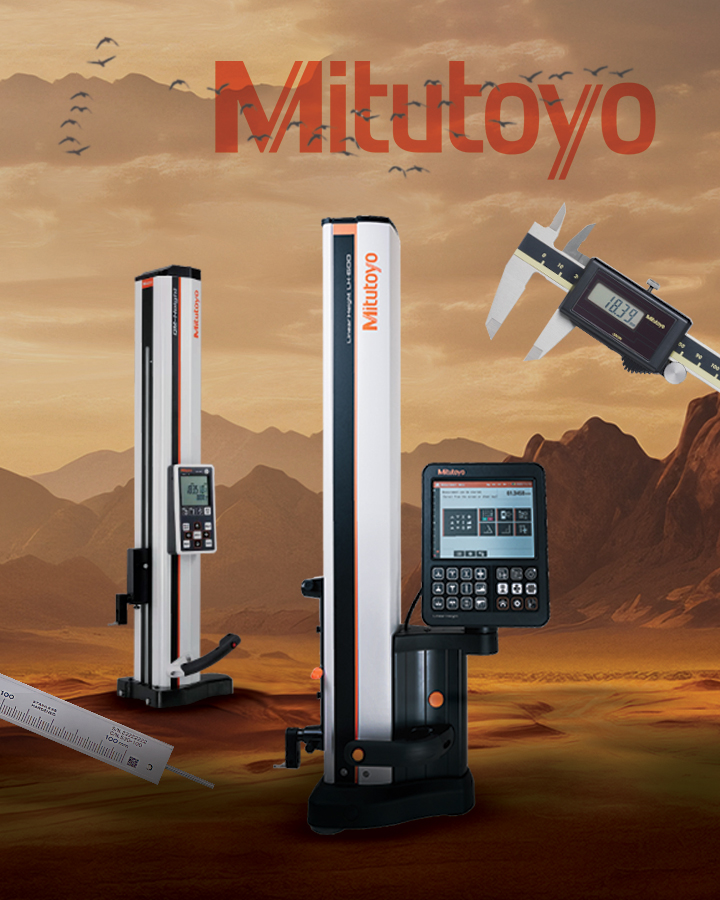

คณะผู้บริหารและตัวแทนจาก MITUTOYO ร่วมประชุมสรุปประจำปี และสวัสดีปีใหม่ 2024 ผู้บริหาร JSR GROUP

คณะผู้บริหารและตัวแทนจาก มิตูโตโย ร่วมประชุมสรุปประจำปี และสวัสดีปีใหม่ 2024